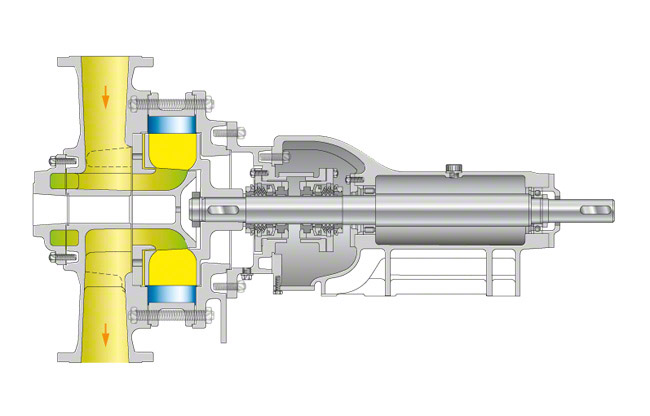

Water ring pumps are liquid ring pumps which work according to the principle of positive displacement (see Positive displacement pump) when partly filled with gas, like side channel pumps Their self-priming capabilities are very good (see Self-priming pump). See Fig. 1 Water ring pump

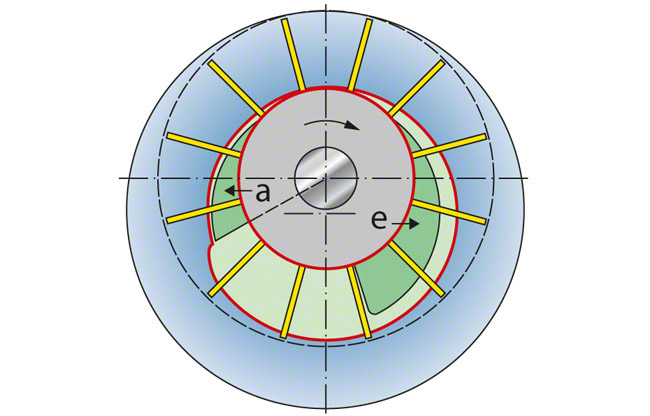

A star-shaped impeller (see Star impeller) rotates eccentrically in a casing, partially filled with liquid, generating a liquid ring with a free surface. The vanes of the star impeller dip into this liquid ring (often a water ring) at varying depths during the course of a revolution. This causes the formation of gas-filled cavities between the vanes and the surface of the liquid. The cavities increase and decrease alternately. In this operating condition the water ring pump is suitable for pumping gas.

When the gas feed ceases (e.g. when the suction line, has been evacuated completely), the water ring pump starts pumping liquid. In this operating mode pump efficiency is usually only moderate. For this reason, priming aids of this type, e.g. for self-priming marine pumps, are stopped manually or automatically when the evacuation process is completed. They are isolated from the suction line, which is now filled with water, and vented. This minimises the power input required for the star impellers.

The effectiveness of a water ring pump is very much dependent on the sealing between star impeller and casing. Narrow clearances at the two flat faces of the casing which accommodate the suction and discharge openings are essential.

Liquid ring pumps are not only used as priming aids for centrifugal pumps but also as vacuum pumps or compressors in the chemical industry.

They are particularly advantageous when the gas to be pumped has to be humidified or compressed without increasing the temperature. An example would be chlorine electrolysis processes in which chlorine gas is isothermally compressed and, simultaneously, scrubbed by concentrated sulphuric acid used as a liquid ring.

At this liquid ring compressor the top and bottom casing halves are designed as eccentric mirror images of each other, so that the star impeller with forward-curvature vanes aspirates and compresses twice per revolution and the compressed gas leaving the discharge nozzle entrains a small amount of liquid. The liquid is then separated from the gas in a separator and cooled by a heat exchanger before being returned to the compressor to maintain the liquid ring. See Fig. 2 Water ring pump