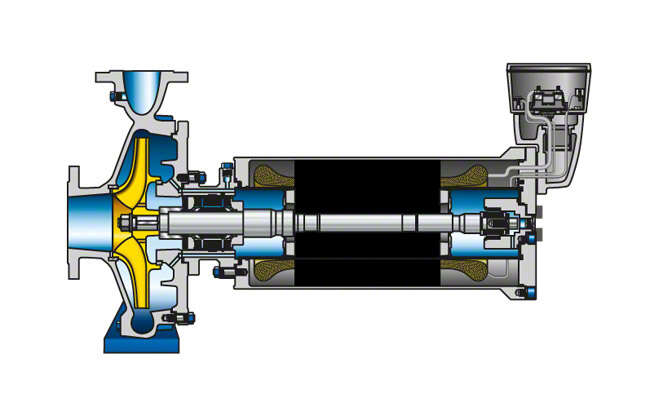

Canned motor

The canned motor is a special type of wet rotor motor, in which the stators winding is protected from the fluid handled by a cylindrical, particularly thin tube (e.g. made from stainless steel or plastic) inserted in the machine's "air gap" (in the gap between stator and rotor). The can must have low or negligible electrical conductivity to avoid insulation and corrosion problems in the stator winding.

Heat dissipation in the stator winding is complicated, however, because efficiency is reduced as a result of the eddy current losses in the can, the increase in the gap between the rotor and stator, and higher friction losses due to fluid friction at the rotor.

The power range of canned motors lies between several watts and approximately 2000 kW. Canned motors are employed wherever hot, aggressive, explosive, toxic or radioactive fluids need to be pumped, which is why a great deal of focus is placed on hermetically sealed pump sets without gland packings or mechanical seals. Canned motors are used for circulators reactor circulating pumps (see Reactor pump), and process pumps for chemical and process engineering applications.

See Fig. 1 Canned motor

Fig. 1 Canned motor pump: Single-stage volute casing pump for general industrial applications