Asynchronous motor

An asynchronous motor has a passive rotor that is short-circuited permanently (squirrel-cage rotor) or temporarily (see Slip ring rotor). It can produce up to several megawatts and is most frequently used as a standard three-phase motor in industrial applications.

The magnetic field in the asynchronous motor is generated by a magnetising current via the electrical energy provided. Asynchronous motors are characterised by slip, i. e. a load-dependent difference between the rotor speed and the speed of the rotary field of the supply voltage.

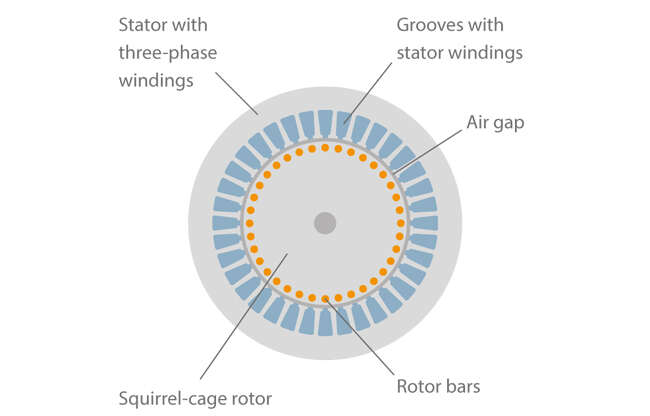

The rotor is a metal cage with axial bars arranged in a symmetric circular pattern and fixed to a short-circuit ring (end ring) at each end.

The stator comprises distributed coils that induce voltage into the bars of the rotor (see Induction) by way of a rotating magnetic field. This results in a high flow of current in the short-circuited bars, which exerts a force between the rotor and stator in the magnetic field and leads to the electromagnetic interaction responsible for the asynchronism. Asynchronous motors are subject to significant losses in the stator and rotor.

In slip-ring rotor motors, the three-phase rotor winding connects to variable resistors – typically used as liquid starters – via the slip rings. This design ensures a soft start-up process that does not place a shock load on the power supply mains and allows the speed to be changed to a certain extent. However, it also produces significant power loss.

The rotor windings of a squirrel-cage rotor generally consist of single or twin conductor bars that are short-circuited at their ends by a ring-shaped conductor. Squirrel-cage rotors are very simple in design and reliable, and they do not require maintenance. See Fig. 1 Asynchronous motor

Fig. 1 Asynchronous motor: Sectional view of asynchronous motor

A distinction is made between dry rotor, submersible and wet rotor motors with respect to water contact. See Fig. 2 Asynchronous motor

Internal wetting | External wetting | ||

Rotor | Winding | Dry housing | Wet housing (submersible |

Dry | Dry | Dry motor (with or without protection | Dry (air-filled) submersible |

Wet (wet rotor motor) | Dry (canned motor) | Wet rotor motor of a glandless pump | Fully submersible |

Fig. 2 Asynchronous motor: Designation of asynchronous motors depending on wetting

The dry motor has different types of protection against ingress of water (see Type of protection).

The submersible motor is partially or completely immersed and is usually installed in a vertical position. Heat generated by the motor is transferred directly to the surrounding fluid handled. Its defining feature is its motor housing, which is wetted from the outside (see Submersible motor pump). Internal wetting and immersion depth distinguish oil- or air-filled submerged motors for small to medium immersion depths (waste water submersible motor pumps) from fully submersible motors.

See Figs. 3, 4 Waste water pump

Fully submersible motors are wetted by the fluid handled on the inside and the outside. They are built for any immersion depth and are above all used in boreholes (see Submersible borehole pumps) which is why they have a small diameter and are relatively long. Fully submersible motors can be equipped with a wet stator winding (including water-tight plastic insulation) or, in conjunction with a can, a dry winding (see Canned motor pump).

The wet rotor motor is filled with a liquid and, unlike the submerged motor, its housing is not wetted from the outside. It has liquid-lubricated bearings (see Plain bearings) and forms a hermetically sealed pump set (glandless pump) together with the pump. The motor can be equipped with a wet stator winding or, in conjunction with a can, a dry winding and is frequently the motor of choice for circulating pumps.