Standardised chemical pump

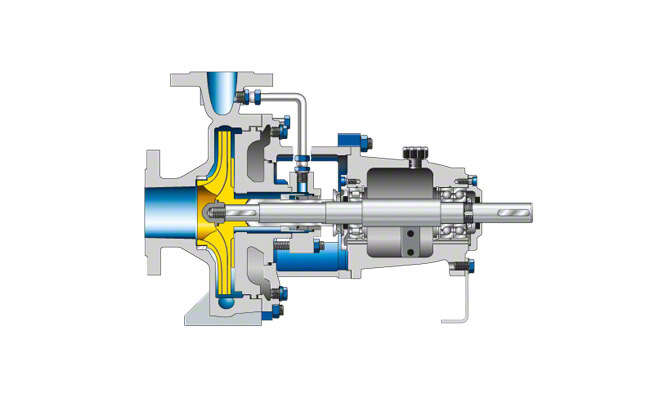

Standardised chemical pumps are chemical pumps, with standardised dimensions and hydraulic output (see Standardised pump). Standardised pumps can be replaced with equivalent pumps of any make. Their back pull-out design enables removal of the bearings including shaft seal and impeller without having to disconnect the pipelines from the pump casing.

If a flexible spacer-type coupling is fitted, the motor does not need to be moved in this process, which means the pump set does not need to be re-aligned after its reassembly. See Fig. 2 Back pull-out design and Fig. 5 Shaft coupling

The main standardised chemical pumps used in the chemical and petrochemical industries are in compliance with EN 22858 / ISO 2858 / ISO 5199 or, in the U.S., ASME B 73.1. See Fig. 1 Standardised chemical pump

Fig. 1 Standardised chemical pump: Pump to EN 22858 / ISO 2858 / ISO 5199

Apart from complying with standards EN 22858 and ISO 2858, which mainly stipulate the dimensions of a pump, chemical pumps often need to fulfil the specifications laid down in ISO 5199, VDMA 24297 and EN 809. These standards stipulate, for example, the maximum permissible vibrations, shaft deflection, noise levels (see Noise in pumps and systems), safety requirements, pipeline forces and moments to be absorbed (see Pump nozzle load) and specify an installation without foundation. The requirements on baseplates for horizontal pumps with a drive are laid down in standard ISO 3661. See Fig. 12 Pump casing