Back pull-out design

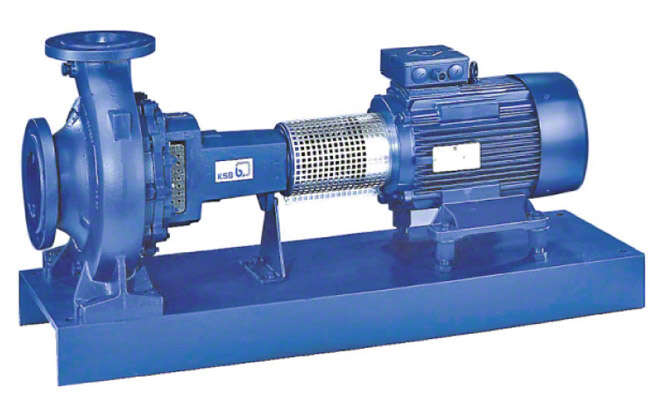

Back pull-out design refers to a centrifugal pump, design type which meets refineries' requirements for rapid dismantling and re-assembly and is therefore often used for process pumps The advantage of this design is that the rotating assembly including bearings and shaft seals can be pulled out of the pump casing once the motor has been decoupled and the connection flange unscrewed. This means that internal components can be inspected and replaced without having to remove the casing from the piping. See Fig. 1 Back pull-out design

Fig. 1 Back pull-out design: Low-pressure centrifugal pump

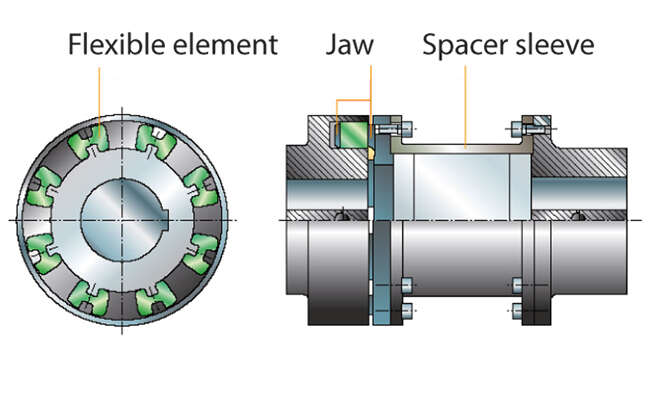

If the shaft coupling used is also fitted with a spacer sleeve, then the motor may remain on the pump foundation even while the rotating assembly is removed. The power cables can also remain installed as the removal of the spacer sleeve towards the side provides sufficient axial clearance for the removal of the rotating assembly.

See Fig. 2 Back pull-out design

See Fig. 2 Back pull-out design

Fig. 2 Back pull-out design: Flexible shaft coupling with spacer sleeve

This maintenance-friendly design has also been adopted for pumps used in other applications in order to ensure efficient deployment of specialist staff.