Pressure exchanger

Pressure exchangers can be used in place of conventional turbine solutions for energy recovery in RO (reverse osmosis) seawater desalination plants.

The pressure exchanger transfers the hydraulic energy in the brine directly to the incoming seawater, referred to as feedwater (see also seawater desalination plant).

See Fig. 1 Pressure exchanger

See Fig. 1 Pressure exchanger

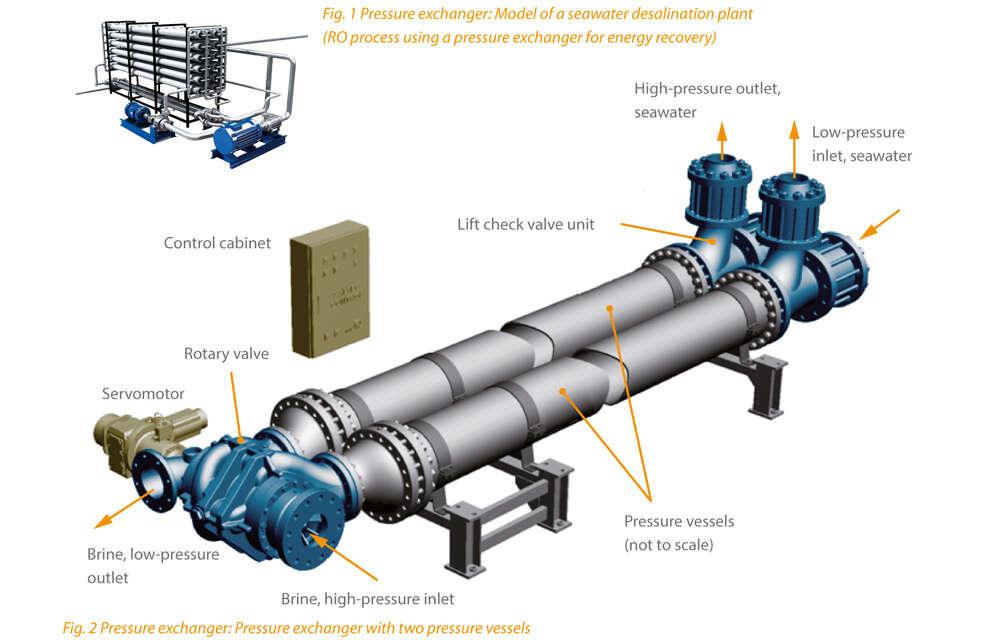

Operating principle with two pressure vessels

- The pressure exchanger comprises two pressure vessels which are operated simultaneously. The check valve unit is installed at one end of the pressure vessels and the rotary valve at the other. See Fig. 2 Pressure exchanger

- The rotary valve is connected to the plant piping through which the brine flows. The check valve unit is connected to the feedwater piping. Each side is equipped

- with one high-pressure and one low-pressure pipe for the seawater and the brine.

- The pressure exchanger is operated in cycles, with each cycle being defined by a 180° rotation of the rotary valve. Each cycle has a low-pressure phase in which the fluid flows from the check valve unit to the rotary valve and a high-pressure phase in which the fluid flows from the rotary valve to the check valve unit. The pressure vessels are filled with seawater in the low-pressure phase, in the high-pressure phase the seawater is pumped into the plant.

- The rotary valve is driven by a servomotor (gearbox). Actuating the valve changes the pressure in the vessels and the flow's direction. As the pressure vessels operate alternately, one conveys low-pressure fluid and the other high-pressure fluid. The fluids in the vessels always flow in opposing directions. Each pressure vessel may be equipped with a piston separating the fluids (seawater and brine).

- Pressures of between 50 and 80 bar are required to desalinate seawater. A high-pressure pump provides the inlet pressure required for the reverse osmosis process. Concentrated brine resulting from this process leaves the membrane modules under high pressure and flows through a pressure exchanger where this pressure is transferred directly to the incoming seawater (feedwater). A recirculation pump then pumps the feedwater to the membranes.

- The pressure exchanger's control unit records and processes all operating conditions in the higher-level reverse osmosis (RO) system in order to optimise operation. It ensures that the water columns in the pressure exchanger vessels are accelerated and decelerated so gently that actuating the rotary valves of the pressure exchanger does not cause pulsations.

- All components including high-pressure and recirculation pumps are made from seawater-resistant materials.

Fig. 1 Pressure exchanger: Model of a seawater desalination plant

Fig. 2 Pressure exchanger: Pressure exchanger with two pressure vessels