Liquefied gas pump

The liquefied gas pump is a centrifugal pump used for handling liquefied hydrocarbons, such as propane, butane, propylene and ethylene, in refineries in the distillation of crude oil. These come under the general heading of LPG (Liquefied Petroleum Gas) and are pumped at about minus 104 ºC.

The liquefied gas pump is also used for handling liquefied natural gas consisting mainly of methane. This is generally known as LNG (Liquefied Natural Gas) and is handled at temperatures around minus 161 °C.

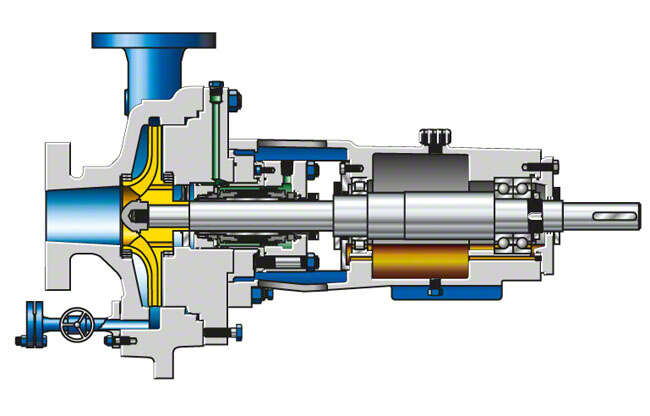

Depending on the application, various types of pumps are used in plants for the liquefaction, vaporisation, filling and storage of LPG and LNG, for example horizontal single or multistage refinery pumps of back pull-out design see Fig. 1 Liquefied gas pump

Fig. 1 Liquefied gas pump: Refinery pump in back pull-out design with double mechanical seal in back-to-back arrangement

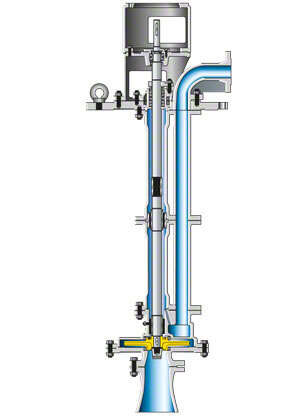

or variants of these type series in the form of vertical pumps.

See Fig. 2 Liquefied gas pump, and Fig. 2 Refinery pump

See Fig. 2 Liquefied gas pump, and Fig. 2 Refinery pump

Fig. 2 Liquefied gas pump: Vertical refinery pump

Multistage, mainly vertical can-type pumps are used for higher heads The shaft passages on these are equipped with mechanical shaft seals.

Depending on the operating conditions, either single metal-bellows mechanical seals or double balanced mechanical seals arranged back to back and with barrier fluid are employed.

As liquefied gases can usually only be pumped at temperatures close to their boiling point (see Vapour pressure) the NPSH required is of great importance (see Suction characteristics). Thus for conventional centrifugal pumps, the NPSH is usually insufficient to enable the tanks to be emptied down to a level of only a few centimetres. This is why it often becomes necessary to use inducers to empty tanks. See Fig. 1 Inducer and inlet conditions

All wetted metal parts of liquefied gas pumps are made of suitable low-temperature materials. Apart from chrome nickel steels, aluminium alloys are also used.