Green hydrogen for tomorrow’s energy

Pumps and valves are essential for the hydrogen transition

An energy source that is practically available in unlimited quantities and can be used without emitting any CO₂? Sounds too good to be true, but it actually is: green hydrogen. No wonder almost all industrial nations are looking towards this element in order to decarbonise their energy systems. Innovations in the field of pumps and valves are making a decisive contribution.

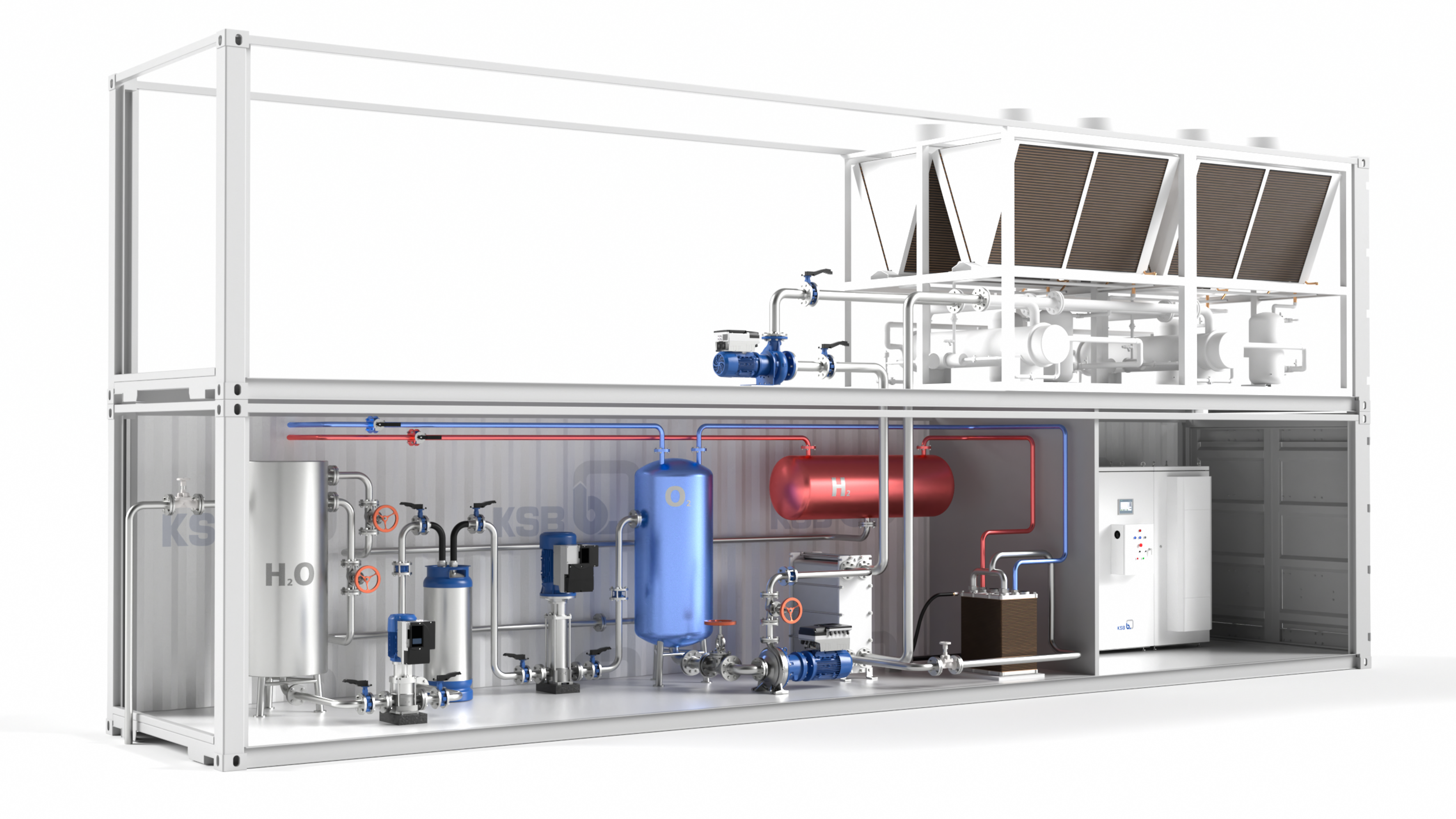

Electrolysers need highly specialised pumps and valves

Pumps and valves play an important part in gaining green hydrogen from the electrolysis of water. In an electrolyser water is split into hydrogen and oxygen with the help of electricity. If the power used is from renewable sources, such as wind or solar energy, the hydrogen is produced in a climate-neutral way and therefore considered "green". This distinguishes it from "grey" or "blue" hydrogen, both of which are generated from natural gas, producing large amounts of carbon dioxide.

Without pumps and valves electrolysis would not work. They keep the main circuit of the electrolyser running, fill the electrolysis cells and transport the mixtures saturated with hydrogen or oxygen to the separators, where the gases are extracted. In addition, electrolysers comprise peripheral circuits and sub-systems, such as for feed water treatment, pressure boosting and cooling, for example. Here, too, further pumps and valves are required.

Electrolysis places high demands on technology

Different electrolysis methods can be used, each of which has got its own challenges that need to be overcome by pump and valve manufacturers. All methods use electrolysis cells containing two electrodes. The one with the negative charge releases hydrogen; the one with the positive charge oxygen. As pure water has got a poor conductivity, electrolysis also requires a substance that conducts electricity, a so-called electrolyte. The methods used differ primarily by the electrolyte used and properties such as pressure, temperatures and efficiency. The specific requirements on pumps and valves differ accordingly. The three most commonly used methods are:

- Alkaline electrolysis (AEL): This method uses caustic potash as an electrolyte. As this is caustic, harmful to health and corrosive, pumps in alkaline electrolysers have to be hermetically sealed and corrosion-resistant. About 60 % of all electrolysers installed worldwide are based on alkaline electrolysis(opens in a new tab).

- Proton exchange membrane electrolysis (PEM): This method uses a solid polymer electrolyte membrane that enables the exchange of protons (positively charged hydrogen ions) but retains the electrons. Like the other methods, PEM electrolysis uses demineralised ultra-pure water. Pumps must not contaminate this fluid under any circumstances, e.g. by sealants or lubricants. The parts in contact with high oxygen concentrations have to be resistant to oxidation. 30 % of the electrolysers installed worldwide use the PEM method(opens in a new tab).

- High-temperature electrolysis (HTE): This method is currently being tested. It uses solid electrolytes, such as zirconium dioxide or yttrium-stabilised zirconium oxide, which are extremely resistant to high temperatures. Electrolysis takes place at above 500 degrees Celsius, which speeds up the reaction and therefore increases the efficiency. About one percent of electrolysers uses the high-temperature method(opens in a new tab).

Competitive prices are decisive for a breakthrough

It is still a very long way for the visions of national hydrogen strategies to be reached, even though the total capacity of electrolysers installed worldwide is currently on a sharp rise. According to information from the International Energy Agency (IAE)(opens in a new tab), about 600 electrolysis projects with a total capacity of more than 160 gigawatts have been announced since 2022. The IAE estimates that by the end of 2023 the global electrolyser capacity may have almost reached three gigawatts, which more than quadruples the figure for 2022. However, these figures cannot hide that water electrolysis only accounts for 0.1 percent of today’s global hydrogen production.

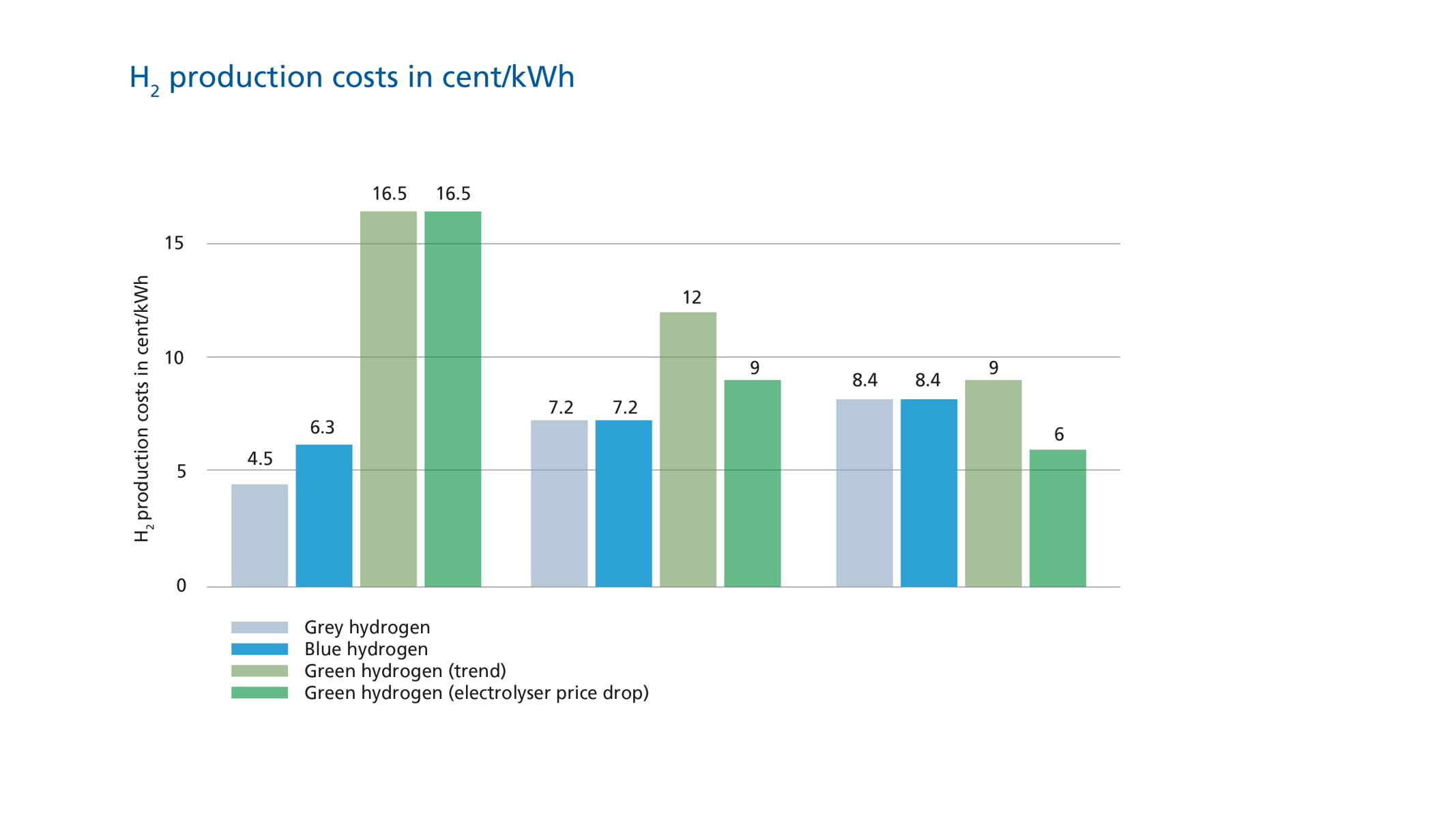

The estimated price development for the different hydrogen production methods: Competitive prices of green hydrogen will be decisive for the energy transition.

For green hydrogen to become the number one choice, it has to be become more cost-effective. This is where innovative components such as pumps and valves play an important role. According to information from Bloomberg(opens in a new tab), in 2023 the average cost of green hydrogen was US$ 6.4 per kilogram, compared to US$ 2.13 per kilogram for grey hydrogen. For green hydrogen to become more competitive, first of all the price of renewable energies has to fall. The installation and operating costs for electrolysers also need to be lower. The International Renewable Energy Agency (IRENA) revealed that the overall costs for electrolysers could fall by 80 percent in the long term(opens in a new tab), if their output improves, production capacities are expanded, and standardisation and scale effects are made use of.

KSB’s innovations contribute to economic efficiency

An important step towards economic efficiency will be building larger electrolysers. When analysing existing projects, the KPMG consulting firm found out (opens in a new tab) that the overall costs per kilowatt of installed electrolyser power are lower the larger the system – with a particularly strong drop in the power range of the first 100 megawatts. Systems at this scale throw up many technical questions: Is a larger capacity best achieved by a large number of modular container solutions using the modular design principle or by single, large systems? This also raises the question of what would be the most efficient way of cooling such large systems.

Extending the service life of electrolysers is another important aspect of lowering the costs of electrolysis. According to information from the International Renewable Energy Agency(opens in a new tab), the current service life of PEM electrolysers is 50,000 to 80,000 operating hours. In the long term, this should be increased to between 100,000 and 120,000 operating hours. Material innovations will play a crucial role in this context.

Decisive are also the standardisation, scale effects and mass production of components for electrolysers. For this reason, KSB not only commits its research and development expertise to customer projects but also contributes to relevant work groups set up by standardisation organisations (e.g. CEN in France and DIN in Germany). Working in close exchange with the industry, KSB has its finger on the pulse of this development. Based on KSB’s development expertise and large portfolio of pumps and valves for systems of the most diverse of sizes, our experts can offer advice on enhancing efficiency and profitability.