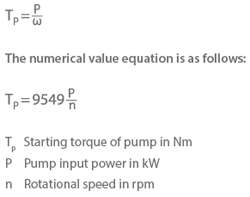

Starting torque

Starting torque is the torque transferred by the shaft coupling during run-up (see Start-up process). It is calculated based on the ratio of power (P) to angular velocity (ω) and is represented as a rotational speed function.

Factors influencing torque:

- Progression of the characteristic curves for the head and pump power input in relation to flow rate and rotational speed.

- Position of the operating point on the characteristic curves

- Run-up behaviour of the drive, as characterised by the run-up time (ta) of the unit (pump and motor)

- System characteristic curve in relation to the valves fitted

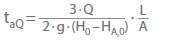

- Run-up time (taQ) for accelerating the liquid mass in the filled piping

taQ Run-up time of the liquid mass in the piping in s

Q Flow rate in m3/s

H0 Shut-off head (head) in m

HA,0 Static part of the system characteristic curve in m

g Acceleration due to gravity in m/s2

L Length of the piping in m

A Cross-sectional area of the piping in m2

To illustrate the possible progression of starting torque at low specific speeds, the head (H), power input (P), and starting torque (TP) of a radial pump are examined under different operating conditions. See Fig. 1 Starting torque

All starting torque curves (Tp) begin with the breakaway torque (TPL) to overcome bearing and seal static friction. They reflect the increase in torque along with rising rotational speed (n) and the increase in power input (P) as a function of increasing flow rate (Q). These processes occur either at the same time or in succession.

In contrast to centrifugal pumps with low specific speeds, a different starting torque curve develops at high specific speeds (e.g. propeller pumps) due to the increasing flow rate and decreasing power input (characteristic curve). More starting torque is therefore required for starting against a closed gate valve (points I and II would be located above line A-B) than for starting against empty, unpressurised piping (point III would be located below the operating point (B)). This characteristic must be observed.