Pulp consistency

Pulp consistency should not be confused with the density of fluids handled and is extremely important in pulp pumping.

A measure of the pulp consistency is given by the percentage by weight of dry substances, a distinction being made between air-dry (% A.D.) and bone-dry (% B.D.).

The German Wood Pulp Manufacturers' Association has laid down a standard moisture content of 12 %. Air-dry pulp therefore contains 88 % of dry solids. A pulp consistency of x % of air-dry pulp therefore corresponds to a pulp consistency of 0.88 · x % bone-dry.

It is usual in the cellulose industry to specify the pulp content in a grams/weight percentage of a 1 kg mixture of pulp and water. This means, for example, that a pulp suspension (mixture of pulp and water) of 30 g bone-dry corresponds to a pulp consistency of 3 % bone-dry. Centrifugal pumps are used for the pumping of pulp suspensions up to pulp consistencies of approximately 7 % bone-dry. This corresponds to a content of 70 kg bone-dry pulp (100 % dry solids) in one tonne of pulp/water mixture.

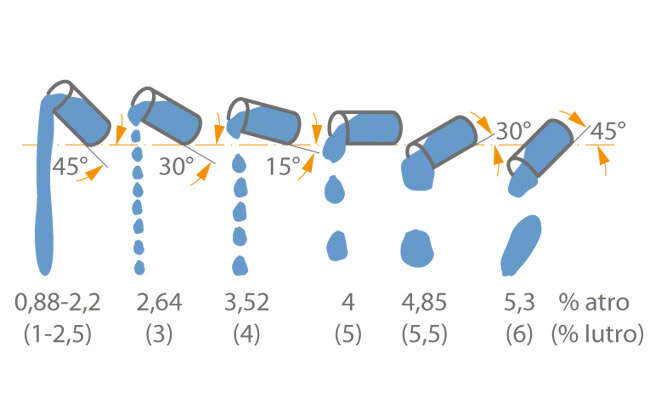

Pulp suspensions with a pulp consistency up to 1 % bone-dry approx. can be considered as pure water as far as their flow characteristics are concerned, in respect of the design of the pumps, valves and piping required to handle them. A very clear picture of the behaviour of higher pulp consistencies can be obtained from the pouring test as a function of the angle of tilt of the container. See Fig. 1 Pulp consistency

Pulp consistencies of up to 3 % bone-dry approx. can be handled by means of conventional centrifugal pumps. Within the region ranging from approx. 3 % to a maximum of approx. 6 % bone-dry, slurry pumps must be used.

Fig. 1 Pulp consistency: Pulp consistency in % bone-dry (in % air-dry)