Pendulum-type electric motor

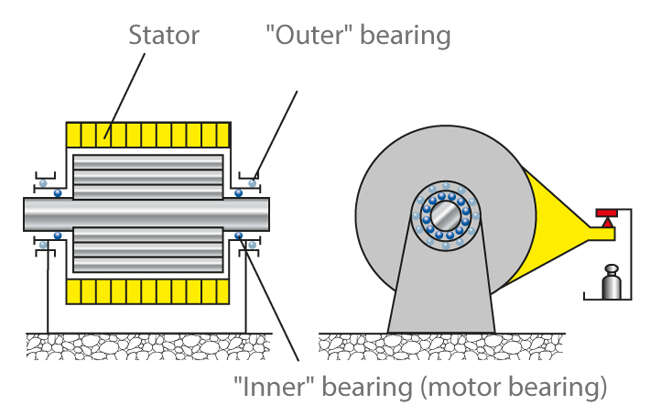

The pendulum-type electric motor of a machine (e.g. centrifugal pump) or the pendulum-type generator of a prime mover (e.g. water turbine) offers very precise measuring options for quantifying torque when configured properly. This variable is determined by quantifying the reluctance torque (counter torque) at the stator of the motor or generator through taking a weight measurement for the known lever arm. To this end, the stator of the pendulum machine must be pivot-mounted about the machine axis. A double bearing arrangement comprising ball or roller bearings is typically used for this purpose (see Rolling element bearing).

If measurement accuracy requirements are very high, the "outer bearings" should be of the hydrostatic (current-free fluids) or aerostatic (current-free gases) type so that only the torque output to the machine or the torque from the prime mover is measured. See Fig. 1 Pendulum-type electric motor

Fig. 1 Pendulum-type electric motor: Schematic diagram

Various losses that occur inside the outer bearings do not influence the measurement. It is therefore beneficial to connect all sources of loss irrelevant to the scenario (e.g. pump bearings) to the oscillating part (stator) for very high measurement accuracy requirements.