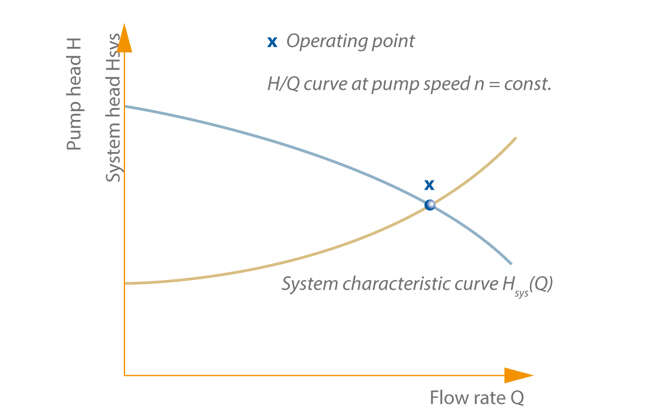

Operating point

The operating point of a centrifugal pump is the intersection of the pump characteristic curve (H/Q curve) and the system characteristic curve Hsys /Q. H/Q is the pump-based variable, Hsys/Q the the system-based variable. See Fig. 1 Operating point

Fig. 1 Operating point: Definition of a centrifugal pump's operating point

The operating point's position shifts if the position or the gradient of the pump characteristic curve H/Q and/or the system characteristic curve.

Hsys/Q change:

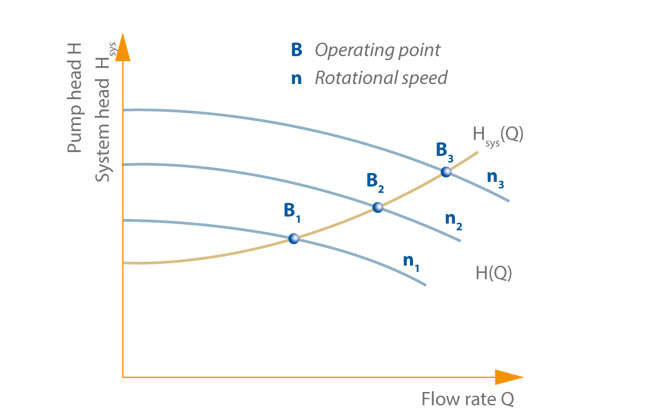

H/Q changes but Hsys/Q remains unchanged:

- This takes place in the case of variable speed centrifugal pumps (see Closed-loop control) (See Fig. 2 Operating point) or

Fig. 2 Operating point: Operating point’s position changes from B1 to B3 on the system characteristic curve Hsys/Q, resulting from an increase in pump speed from n1 to n3

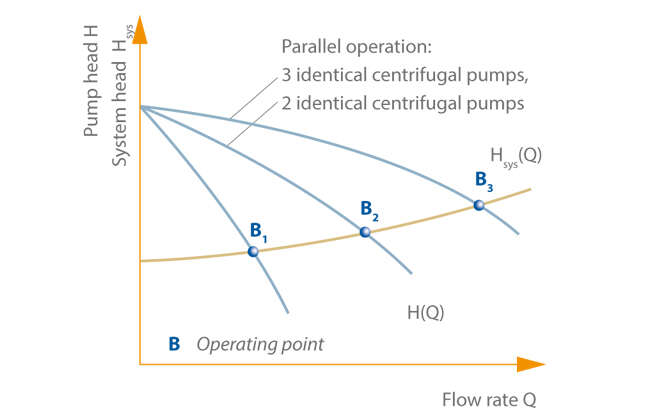

- When centrifugal pumps of the same size are started up and operated in parallel. See Fig. 3 Operating point

Fig. 3 Operating point: Operating point’s position changes from B1 to B3 on the system characteristic curve Hsys/Q when starting a second and third identical pump in parallel

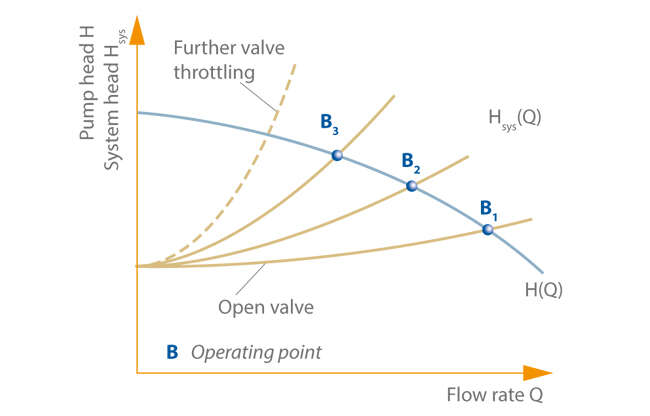

Hsys/Q changes but H/Q remains unchanged:

- The system characteristic curve may change during operation as a result of increased head losses (e.g. throttling via check valves, pipe incrustations) or changes in static head (e.g. fluid level fluctuations in tanks).

- Exact correspondence between the design and duty points (the latter referring to those specified by the customer) and the operating points only exists in rare cases. The operating point is often matched to the required data by throttling. See Fig. 4 Operating point

Fig. 4 Operating point: Operating point’s position changes from B1 to B3 on the pump characteristic curve H/Q as a result of increased throttling