Mercury pump

A mercury pump transports mercury in chlor-alkali electrolysis processes based on the mercury cell method. In this process, a layer of mercury flowing across the bottom of the electrolytic cell serves as the cathode, which is where an amalgam is formed. In a second cell a decomposer transforms the amalgam into mercury, an alkaline and hydrogen. The mercury is then returned to the electrolytic cell by the mercury pump.

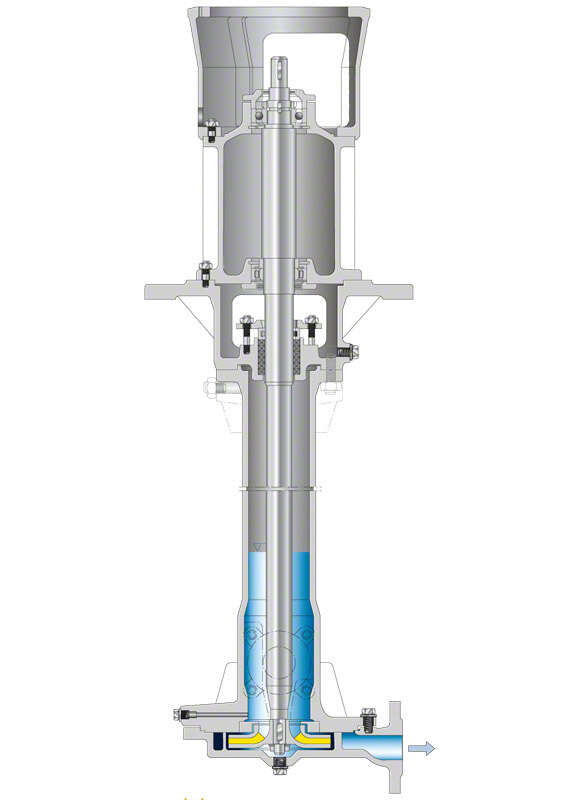

Most mercury pumps are vertical, dry-installed centrifugal pumps, which are mounted on the side of the electrolytic cell or the decomposer. They are positioned for the mercury level above the upward-facing impeller inlet to be kept as low as possible.

The pump shaft with overhung impeller is supported by grease-packed rolling element bearings and designed for uncritical operation. The shaft seal is not in contact with the fluid handled. It is a gland packing arranged in the support column at a suitable distance above the mercury level. It is often supplied with barrier water and serves to prevent any leakage of water polluted with mercury as well as any ingress of dirt. Using double mechanical seals supplied with barrier water prevents any leakage of mercury at the shaft seal. Using seal-less canned motor pumps ensures leakage-free operation. See Fig. 1 Mercury pump

Fig. 1 Mercury pump: Vertical single-suction pump with radial suction and discharge nozzles