Measurement uncertainty

Measurement uncertainty as defined by DIN 1319, page 3, encompasses the random errors of all individual quantities from which the measurement result is calculated and errors that are not recorded because they cannot be quantified and thus represent estimated, systematic errors. It is relevant to metrology applications.

The systematic measurement uncertainty of individual measurement methods and measuring instruments must be determined using information provided by the manufacturers of the measuring instruments. These devices must be calibrated as required, whereby systematic measurement uncertainty can be reduced to that of the calibration unit.

Every measurement taken is inextricably subject to measurement uncertainty, even if the measurement methods, devices, and evaluation requirements fully comply with the relevant acceptance test codes.

When the test results are compared to the guaranteed values, the measurement uncertainty must be suitably taken into account in a way that is not influenced by the pump and the guaranteed values (see DIN EN ISO 9906).

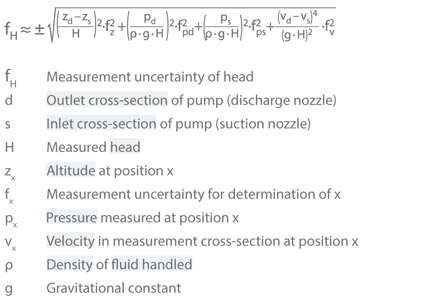

If the characteristic value of a pump, such as the head, is calculated from several (different) measurands, the measurement uncertainty for these must be determined by geometric addition (root of the sum of squares) of the measurement uncertainties of the individual quantities:

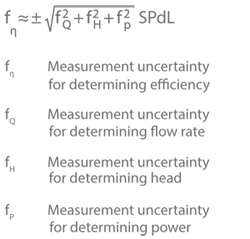

Measurement uncertainty is determined in a similar manner when a value calculated from different measured values is assessed. Efficiency, for example, primarily comprises the measurement results for the flow rate, head, and pump input power, the measurement uncertainties of which determine that of efficiency.

Defined total measurement uncertainties can be used if no special tolerance values are provided by the device manufacturers. See Figs. 1, 2 Measurement error