Damage

The term "damage" refers to a change in a component that impairs or prevents its intended function (see VDI (Association of German Engineers) Directive 3822).

Damage is identified by carrying out damage analyses. These comprise systematic investigations and tests to determine how the damage has evolved and its underlying causes. In addition to triggers associated with manufacturing (such as casting defects or shrinkage cavities in castings), the main causes of damage to centrifugal pumps are usage-related.

Causes of damage

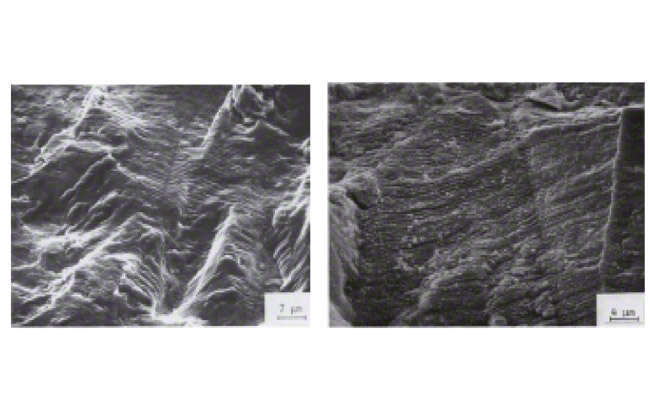

- Mechanical stress: Ruptures of any kind. A distinction is made between tough or brittle (tensile, compressive, bending or torsional) forced fractures/ruptures that may, in turn, be attributable to a fatigue failure. The associated damage characteristics, causes and patterns are described in VDI (Association of German Engineers) Directive 3822, Sheet 2. See Fig. 1 Damage

- Aggressive fluids: These often cause consequential damage through corrosion. If components are subjected to corrosive and mechanical stress, stress corrosion cracking or corrosion fatigue may occur, resulting in damage. The characteristics, causes and patterns are described in VDI (Association of German Engineers) Directive 3822, Sheet 3.

- Wear: This occurs when components rub against one another or when the fluid handled comes into contact with a component.

Fig. 1 Damage: Appearance of a fractured surface following rotating bending/vibration fatigue failure