Condition monitoring

Condition monitoring is a concept for keeping track of a product's states so that safety and machine efficiency can be ensured. Within this context, sensors are used to take regular measurements in order to provide meaningful values such as vibration and temperature data.

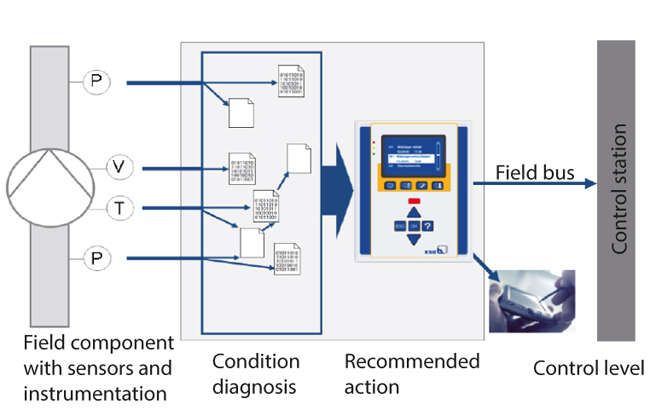

For this purpose, condition monitoring relies on the infrastructure of a communications system. Condition monitoring is based on analysing sensor data in real time. It is these data that make it possible to implement a reliable and highly responsivesafety system (e. g. for emergency shutdown). This enables precise analysis of the disruptive factors so that all you have to do is replace the destroyed component. Before the advent of this new concept, (preventive) maintenance was carried out at set intervals, which meant that even fault-free components were replaced in certain circumstances. See Fig. 1 Condition monitoring

Fig. 1 Condition monitoring: Example of condition monitoring on a pump (P = pressure; T = temperature; V = volume flow rate)

Aspects of condition monitoring

- Condition detection (measurement and documentation of the current machine values)

- Condition comparison (comparison of actual values with reference values (e.g. limits or setpoint values)

- Diagnostics (pinpointing of any errors that may be present with a view to planning necessary maintenance measures)