Cavern pump

Cavern pumps are a special type of tank farm pumps. Caverns can take the form of salt deposits, old mines, depleted oil and gas fields, porous storages and blasted-out mine workings. Depending on the type of cavern, either above-ground, multistage high-pressure pumps or submersible borehole pumps of special design are used.

To ensure tightness of mine workings a water jacket is placed around the cavern. The pressure of the water must be somewhat higher than the vapour pressure of the stored medium. This enables oil caverns in depths of up to 60 m to be used; for storage of propane and butane, some 140 m.

Cavern systems are operated mainly using submersible motor pumps that are also known as submersible borehole pumps for use in tank farms.

They are equipped with submersible motors.

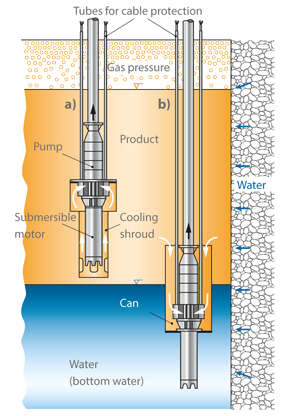

See Fig. 1 Cavern pump

Fig. 1 Cavern pump: Cavern system

The design of submersible motor pumps used for LPG caverns (propane and butane) does not provide for pressure equalisation diaphragms, as otherwise the LPG would diffuse into the motor space. The motors are therefore designed to be pressure-resistant up to 25 bar and subjected to static pressure from an above-ground water tank. LPG can even potentially diffuse into the connecting cables. Since cable protection pipes are impractical at this depth, the cables are provided with an outer reinforcement to prevent breaks during removal.

The area of application of a cavern pump's submersible motor depends on the surrounding temperature and cooling systems.

See Fig. 2 Cavern pump

Fig. 2 Cavern pump: Cooling of submersible motors with a) cooling shroud; b) can

Cooling systems of a submersible motor

- Cooling jacket (the fluid handled is fed around the motor to remove the heat lost from the motor) See Fig. 2-a Cavern pump

- Surrounding leakage water (a can must be fitted in this case to separate the oil from the water) See Fig. 2-b Cavern pump

- Circuit cooling (connection of the motor to a cooling circuit e.g. via the cable protection pipe)

Both product and leakage water pumps are used in the caverns.

Product pump

The product pump is used to pump the product out of the cavern. The density and viscosity of the product must be taken into account when selecting the pump and motor.

In order to keep the viscosity at a low level when handling heavy, highly viscous fuel oils to ensure economic operation, the oil is heated to a temperature of 60 to 95 °C.

The motors of product pumps provide a flange connection for a safety valve.

In order to keep the viscosity at a low level when handling heavy, highly viscous fuel oils to ensure economic operation, the oil is heated to a temperature of 60 to 95 °C.

The motors of product pumps provide a flange connection for a safety valve.

Leakage water pump

A certain amount of leakage water always penetrates into the cavern from the surrounding rock. This water accumulates at the bottom of the cavern because of its higher density compared with the product, and must not exceed a certain level. The leakage water pumps are designed to maintain a reasonably constant water level and often need to be made of seawater-resistant material such as bronze or chrome nickel steel since many of the caverns are situated near the sea and the leakage water often is seawater (see also Seawaterpump).