Back-to-back impeller pump

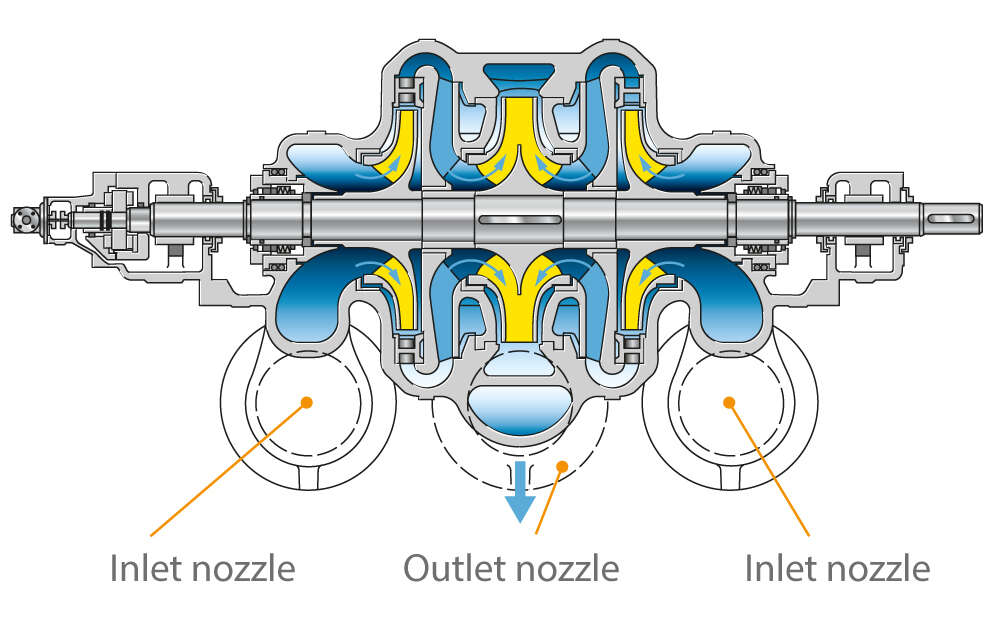

Back-to-back impeller pumps are fitted with several impellers in back-to-back arrangement on a common pump shaft This is an effective means of balancing the axial thrust occurring during the operation of a centrifugal pump without requiring a separate balancing device. The axial flow approaches the corresponding pair or group of impellers from opposite directions. Diese Bauweise bietet sich bei double-suction pumps such as centrifugal pumps with a double-entry impeller can also be used for multistage pumps such as pipeline pumps or boiler feed pumps. See Fig .1 Back-to-back impeller pump

Fig. 1 Back-to-back impeller pump: double-suction, two-stage volute casing pump with axially split casing

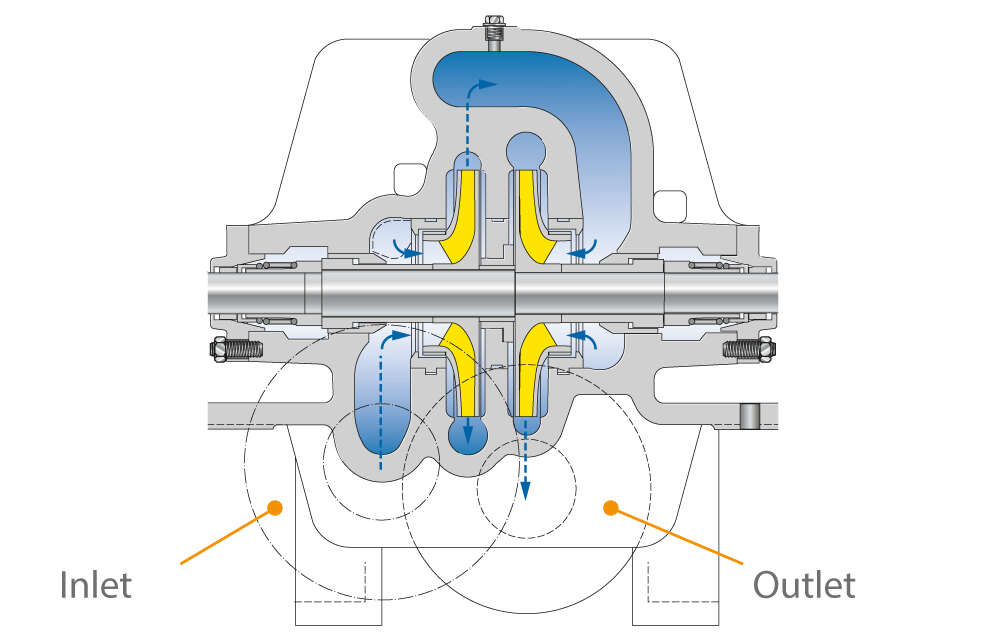

A pump casing of axially split design is required for the necessary crossover channels. As this type of casing tends to be rather long and relatively costly, back-to-back impeller pumps with more than one impeller pair are only used if the costs which would be incurred in the event of a failure or consequential damage (e. g. failure of a balancing device) justify this expense. See Fig. 2 Back-to-back impeller pump

Fig. 2 Back-to-back impeller pump: Two-stage, single-suction volute casing pumps with crossover channels and axially split casing