Pump repair results in impressive increase in pressure and energy savings

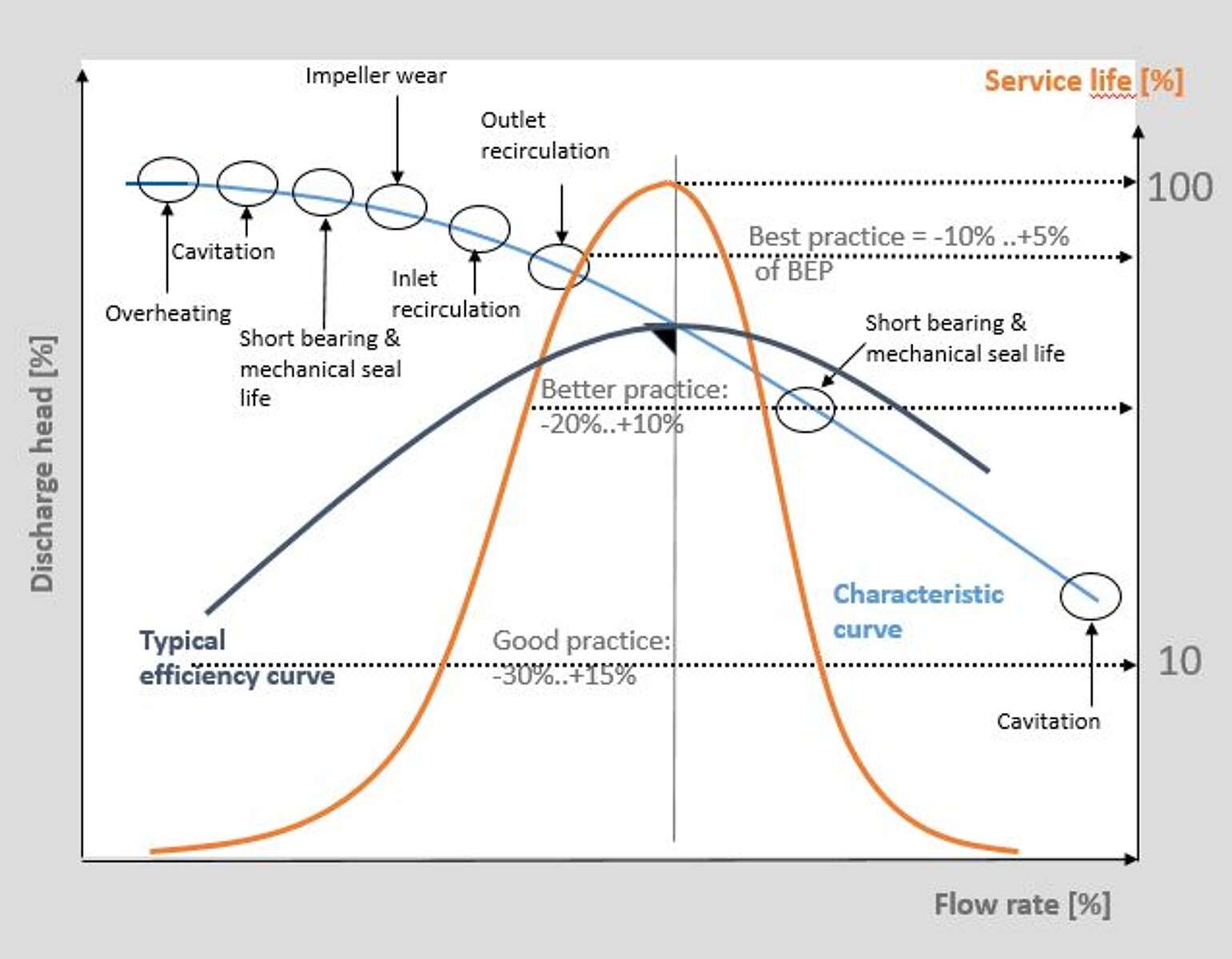

It is one thing to understand in theory the importance of properly matching your pump to your system and operating close to its Best Efficiency Point (BEP,) but the reality is that doesn’t always happen.

Sometimes you find yourself between a rock and a hard place: your budget is tight and you resort to using an old pump in a new system without any hydraulic adjustments. At first the system may seem to work well enough. But eventually operating so far from its BEP will take a toll on the pump you won’t have an option but to open it up for repairs.

Challenge: Diagnose and repair severe cavitation damage

This is exactly what happened for a steel plant in Ontario. Eventually their system did see enough performance issues from this split case pump to require them to take it out of operation and call the experts at KSB SupremeServ to help. KSB SupremServ has two rotating equipment Service Centres in Canada that are fully equipped to handle nearly any size pump.

Upon removing the upper case, KSB SupremeServ centre in Mississauga discovered that large chunks of metal had been completely worn away in a number of places on both the upper and lower casing cutwaters.

The location of this damage, localized at the cutwaters on the suction sides of both the upper and lower casings, indicated the cause was cavitation damage due to internal recirculation. Cavitation damage most often causes pitting that looks like holes in a sponge, but the damage here was so severe it had eaten away entire chunks of metal.

“When the hydraulics are off, and the flow isn’t smooth, recirculation can create a vacuum and form bubbles (cavities). When those bubbles implode, pressure surges damage the pump,” KSB Service Manager Mike Kruis explained.

Solution: KSB SupremeServ rebuilds the cavitated areas of the casing cutwaters

The KSB Service team used a metal grating in addition to a metal fill compound to build the damaged cutwaters back up, repairing the severe cavitation damage. A number of damaged parts were also repaired or replaced: the shaft protector sleeve, bearings, gaskets and casing wear rings.

Finally, the interior casings were grit-blasted and coated with a durable, friction-resistant ceramic coating to protect against future damage and extend the life of this split case pump, despite its suboptimal match to its system.

Results: Improved hydraulics increased discharge pressure by 25%, resulting in significant energy savings

The rebuilt cutwaters eliminated the recirculation problem, significantly improving the hydraulics. The steel plant saw a 25% increase in discharge pressure with the repaired pump, resulting in substantial energy savings.

"We really do understand that a properly sized pump isn’t always in the budget. But there is always something we can do to improve pump performance even in less than ideal circumstances.” Kruis explains. “Our job is to help find the best solution given your situation, there are always options."