Main Applications

- Hot-water heating systems

- Air-conditioning systems

- Cooling circuits

Technical Data

- Nominal pressure

- PN 16, PN 25

- Max. nominal size

- DN 150

- Maximum allowable fluid temperature

- 120 °C

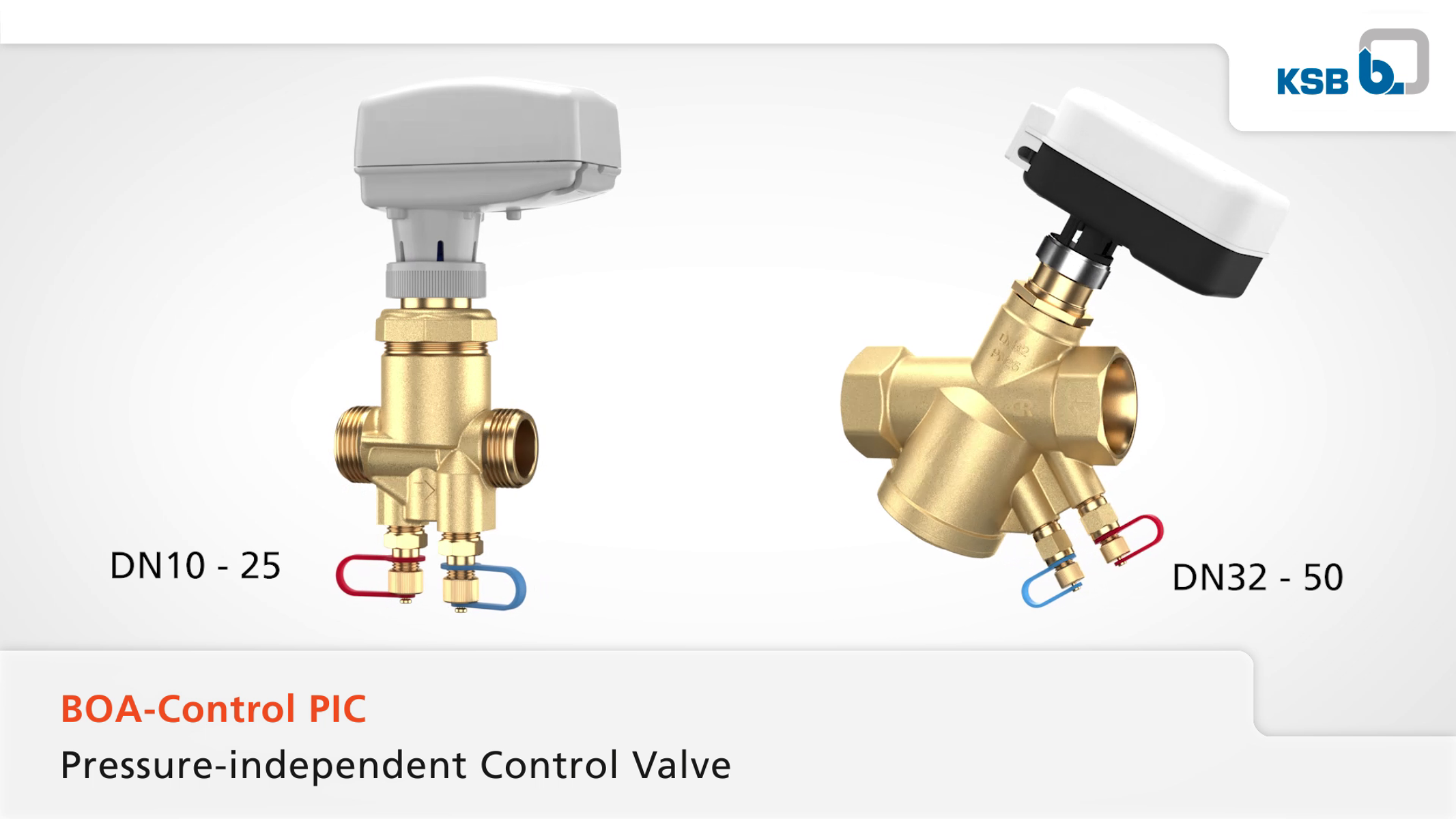

One valve, two functions, maximum flexibility: BOA-Control PIC

The BOA-Control PIC pressure-independent control valve takes care of both, dynamic balancing and comprehensive control functions. Zoning into press-independent system sections and consumers results in optimum behaviour in part and full load operation. You benefit from: energy efficiency, operating reliability and maximum living comfort – coupled with straightforward installation and selection, following the motto "Plug & Play".

Watch the product video for further details.

One valve, two functions, maximum flexibility: BOA-Control PIC

The BOA-Control PIC pressure-independent control valve takes care of both, dynamic balancing and comprehensive control functions. Zoning into press-independent system sections and consumers results in optimum behaviour in part and full load operation. You benefit from: energy efficiency, operating reliability and maximum living comfort – coupled with straightforward installation and selection, following the motto "Plug & Play".

Watch the product video for further details.

Material number list – BOA-Control PIC

14 productsMaterial number | Status | Estimated delivery | Price | |||

|---|---|---|---|---|---|---|

| BOA-CONTROL PIC PN 16 DN 65 | 21.6 kg | 48016937 | Loading... | Loading... | Loading... | |

| BOA-CONTROL PIC PN 16 DN 80 | 28.1 kg | 48016938 | Loading... | Loading... | Loading... | |

| BOA-CONTROL PIC PN 16 DN100 | 33.6 kg | 48016939 | Loading... | Loading... | Loading... | |

| BOA-CONTROL PIC PN 16 DN125 | 46.4 kg | 48016940 | Loading... | Loading... | Loading... | |

| BOA-CONTROL PIC PN 16 DN150 | 75.4 kg | 48016941 | Loading... | Loading... | Loading... |

Benefits

- Materials suitable for all applications in heating or cooling systems

- Quick and straightforward commissioning by presetting the volume flow rate

- Constant volume flow rate by mechanical volume flow rate control

Technical Data

- Function

- Shut off/control flow

- Connection type

- External-thread connection,

Internal-thread connection,

Flange - Design concept Drive

- With handwheel

- Casing material

- EN-GJL-250,

CW602N - Nominal pressure

- PN 16,

PN 25 - Max. nominal size

- DN 150

- Min. nominal size

- DN 10

- Maximum allowable fluid temperature

- 120 °C

- Minimum allowable fluid temperature

- -10 °C

Sectional Drawings

BOA-MP

Measuring pipe with integrated ultrasonic sensors for identifying flow direction and measuring volume flow rate and temperature, sensors not in contact with fluid handled, constant measuring accuracy independent of minimum differential pressures. Stationary monitoring by means of BOATRONIC 100 MOD (24 V AC/DC, Modbus) of flow direction and volume flow rate; optional measurement of supply and return temperature, thermal output and quantity of heat. Mobile measurement of flow direction, volume flow rate and temperature using the BOATRONIC 100 measuring computer (rechargeable battery powered).

BOA-Control SBV

Maintenance-free balancing and measurement valve with female threaded ends, Y-pattern, continuous presetting, with position indicator readable from all angles (360°). Includes travel stop and 2 measurement ports with fixed measuring orifice (tolerance +/- 5 %) for measuring pressure, differential pressure and flow. Minimum space requirements thanks to non-rising handwheel and all functional parts being positioned on the same side as the handwheel.

BOA-Control/ BOA‑Control IMS

Balancing, measurement and shut-off valve with flanged ends to DIN/EN, constant measurement accuracy independent of differential pressures. Body in standard face-to-face length to EN 558/1, throttling plug, scaled position indicator, travel stop and insulating cap with anti-condensation feature; maintenance-free, full insulation possible. Also available with electrostatic plastic coating (EKB) and DVGW-certified for drinking water. With integrated ultrasonic sensors not coming into contact with the fluid handled. Stationary monitoring by means of BOATRONIC 100 MOD (24 V AC/DC, Modbus) of flow direction, volume flow rate and temperature, and optional recording of supply and return temperature as well as thermal output and quantity of heat. Mobile measurement of flow direction, volume flow rate and temperature using the BOATRONIC MS (battery powered) / BOATRONIC 100 (rechargeable battery powered) measuring computers.

BOA-Control DPR

Differential pressure control valve / proportional control valve for the constant control of an adjustable differential pressure setpoint without auxiliary energy, with threaded ends (DN 15 - 50) or flanged ends (DN 65 - 100). Setpoint can be adjusted continuously and read from the outside at any time. The valve closes automatically with rising pressure. Includes quick-measurement ports for measuring pressure loss. Available in various pressure control ranges (LP/HP) from 5 to 80 kPa (threaded ends) and from 80 to 160 kPa (flanged ends).

BOA-Systronic ePIC

Smart and pressure-independent measurement and control valve (2-way energy valve) for monitoring and controlling flow direction, volume flow rate, supply and return temperature, thermal output and quantity of heat as well as automating the hydraulic balancing process. With integrated ultrasonic flow rate measurement and temperature sensor not in contact with the fluid handled; includes: 2 additional Pt1000 temperature sensors for measuring the supply and return temperature, integrated basic control functions (position, flow rate, temperature, thermal output), integrated process optimisation functions (delta-T management and limitation features). Also available with electrostatic plastic coating (EKB) and DVGW-certified for drinking water.

BOA-CVE C/CS/W/IMS/EKB/IMS EKB

Control valve to DIN/EN based on standard type series BOA-Compact, BOA-SuperCompact, BOA-W, BOA-Compact EKB, BOA-Control IMS and BOA-Control IMS EKB, bonnetless pressure-retaining body, soft-seated. Leakage rate selectable from 0.05 % to drop-tight, Kvs values between 6.3 and 700 m³/h and closing pressures of up to 16 bar. With intelligent microprocessor-controlled and pre-set electric actuators providing actuating forces from 1000 N to 14,000 N; electronic configuration of flow characteristic, Kvs value, actuating signal and actuating time using PC tool or manual parameterisation unit. Customised configuration can be implemented at the KSB factory on request.

BOA-CVE H

Service-friendly control valve to DIN/EN with flanged ends, either with linear or equal-percentage control characteristic at Kvs values of 0.1 to 630 m³/h and closing pressures of up to 40 bar; all internal parts are easy to replace without special tools, including the reversible seat; noise level reduced by standard two-stage pressure reduction combining a parabolic plug and multi-hole cage; with electric actuator.

BOA-CVP H

Service-friendly control valve to DIN/EN with flanged ends, either with linear or equal-percentage control characteristic at Kvs values of 0.1 to 630 m³/h and closing pressures of up to 40 bar; all internal parts are easy to replace without special tools, including the reversible seat; noise level reduced by standard two-stage pressure reduction combining a parabolic plug and multi-hole cage; with pneumatic actuator.