To protect the climate successfully, we need to reduce the percentage of fossil fuels in the energy mix to a minimum and promote the further expansion of renewable energies. Hydrogen is seen as one of the most promising forms of renewable energy. When produced in a climate-neutral way, it can significantly reduce carbon emissions far beyond the electricity sector. In Germany alone, hydrogen generation plants with a total capacity of up to ten gigawatts are to be built by 2030 – and KSB offers cutting-edge solutions for achieving this.

Contact us

The challenging path to a sustainable hydrogen economy

To protect the climate successfully, we need to reduce the percentage of fossil fuels in the energy mix to a minimum and promote the further expansion of renewable energies. Hydrogen is seen as one of the most promising forms of renewable energy. When produced in a climate-neutral way, it can significantly reduce carbon emissions far beyond the electricity sector. In Germany alone, hydrogen generation plants with a total capacity of up to ten gigawatts are to be built by 2030 – and KSB offers cutting-edge solutions for achieving this.

Contact us

We are putting all our energy into driving hydrogen as an energy source

Hydrogen technology will play a key role in the energy supply of the future because it offers numerous advantages. First, the production of ‘green’ hydrogen using electrolysers is carbon neutral and relatively simple. Electrolysis is the process of passing electricity (in this case from renewable sources such as wind, hydropower or photovoltaics) through water, i.e. H2O, via an anode and cathode in order to split the water molecules into hydrogen and oxygen. The two gases are separated and then processed so they are available for further use. Hydrogen produced in this way can be used in a variety of applications – for example to store energy, produce climate-neutral fuels, power vehicles or as a raw material for use in the steel and chemical industries.

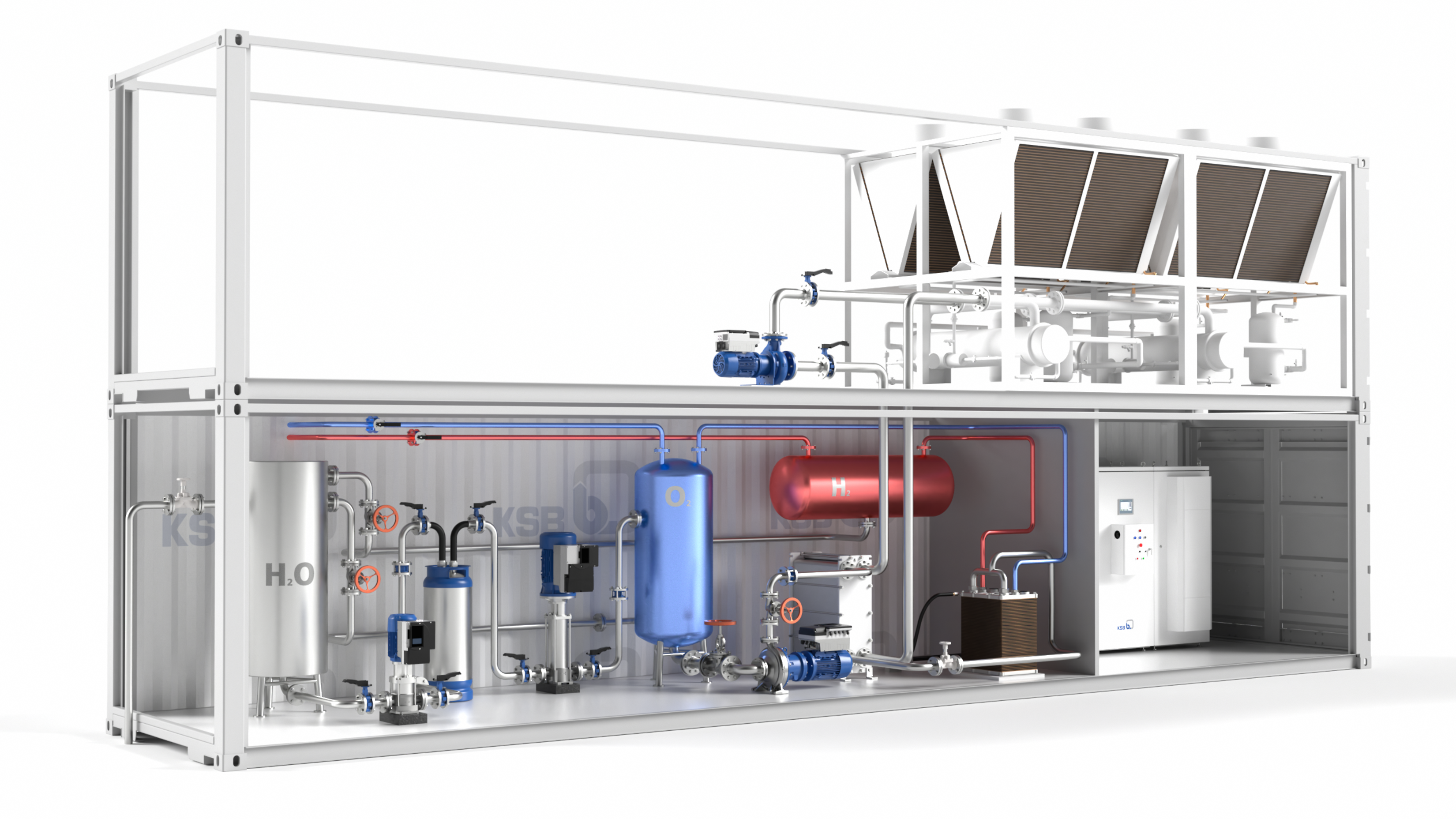

Hydrogen electrolyser as a compact container solution: The flow rate here is around 10 m3/h.

Suitable pumps and valves play a crucial role in the transition to hydrogen. As an experienced manufacturer in the field of industrial and chemical processes, we have a wide range of products and a detailed knowledge of systems engineering, operating modes, materials and energy efficiency.

When it comes to the various technologies for producing green hydrogen, we are perfectly equipped. Our solutions are compatible with all major green hydrogen production technologies – from alkaline electrolysis (AEL) and proton exchange membrane electrolysis (PEM) to future technologies such as anion exchange membrane electrolysis (AEM) or high-temperature electrolysis (HTEL). And of course, as a full-range supplier with comprehensive expertise, we also offer ideal solutions for the production of blue, grey or turquoise hydrogen.

Regardless of which processes are used in the future and which plant size or type of electrolyser proves to be more effective, KSB’s portfolio covers all stages of the hydrogen value chain as well as different power-to-X technologies – from production, transport and storage through to the use of hydrogen.

In addition to research activities and a wide range of funded projects, we are keeping a close eye on emerging hydrogen business models and technologies – all with the aim of developing this technology for a greener future and promoting the advancement of the hydrogen economy. We are committed to creating a more environmentally friendly future together with you. Welcome to the world of green solutions!

All you need to know about hydrogen:

Timeline: from industrialisation to the energy transition