Main Applications

- API 682 applications in the chemical and petrochemical industries

Technical Data

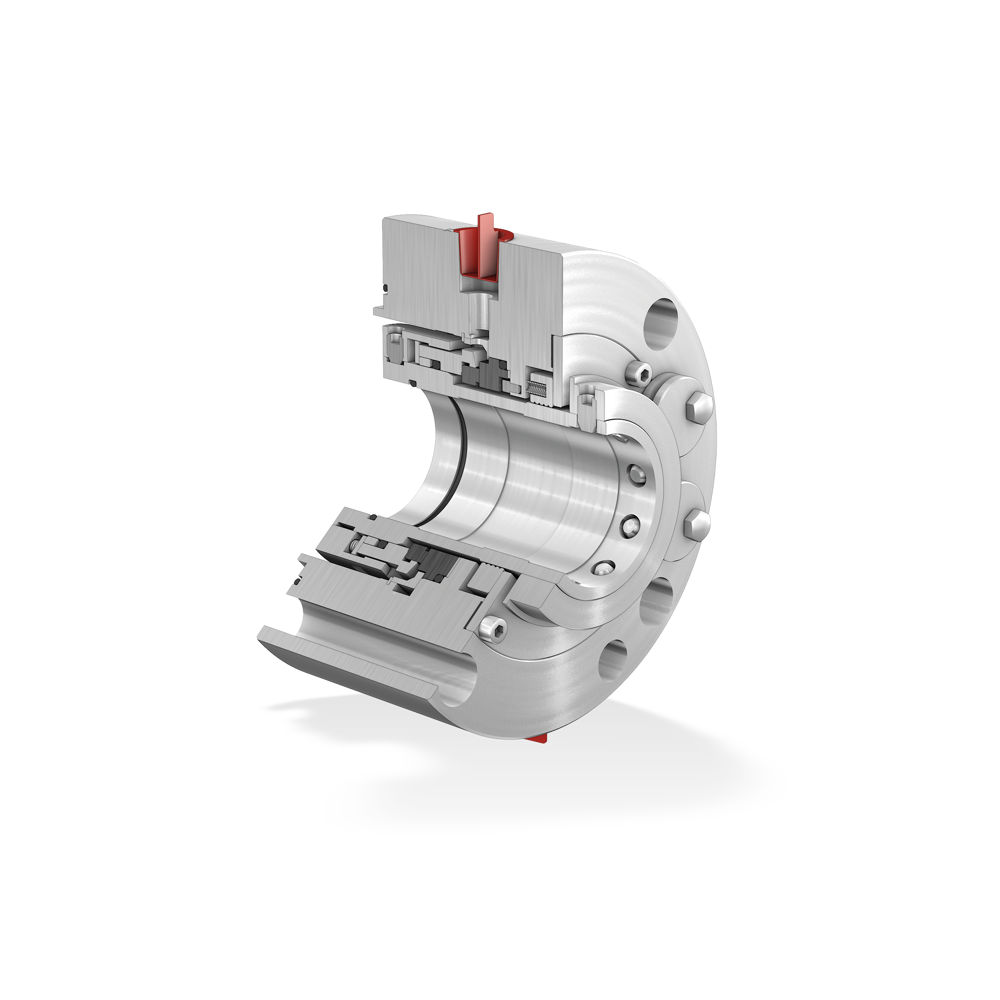

- Cartridge seal

- Yes

- Design Mechanical seal

- Dynamic

- Mechanical seal type

- Balanced mechanical seal

- Sealing type Mechanical seal

- Single

- Max allowed fluid temp TSG

- 200 °C

Benefits

- The single cartridge seal can be connected in accordance with all common API Plans, such as 01, 02, 11, 31, 32 + 61 (62) and 23 + 61 (62). The seals are available for all of KSB's API pumps.

- The throttling bush enables connection of a gas, steam or liquid quench, depending on the seal variant. This prevents outboard deposits at the seal, for example.

- The API Plan combination 02 + 23 with high-efficiency pumping ring is perfectly matched to applications handling hot fluids.

Technical Data

- Max allowable axial movem TSG

- 2 mm

- Min allowable axial movem TSG

- -2 mm

- Cartridge seal

- Yes

- Max allow.dynamic pressure TSG

- 40 bar

- Design Mechanical seal

- Dynamic

- Mechanical seal type

- Balanced mechanical seal

- Sealing type Mechanical seal

- Single

- Mtrl metallic compon.mech.seal

- 1.4571

- Mtrl mech.seal spring

- 2.4610

- Mtrl Secondary seal inboard

- FKM,

FFKM - Mtrl Mating ring inboard

- Q2 [SIC-C-SI, COMPOSITE]

- Mtrl Primary ring inboard

- A [CARBON, METAL-IMPREGNATED],

Q2 [SIC-C-SI, COMPOSITE] - Dir of rotation Mech seal

- Bi-directional

- Max allow.sliding speed TSG

- 23 m/s

- Spring design Mechanical seal

- Multiple springs

- Max allow.static pressure TSG

- 40 bar

- Max allowed fluid temp TSG

- 200 °C

- Min allowed fluid temp TSG

- -10 °C