When Sophie does up her dancing shoes, a piece of Eta lies at her feet.

Whether as a profession or a hobby, regularly or just now and then on the weekend, in a dance school, a night club or at home: Getting down on the dance floor revitalises the body and mind. “Dancing is like dreaming with your feet.”

This is where Eta comes in: Where you are happy to be able to dance on a nice wooden floor, chances are that Etanorm SYT contributed to its production.

Parquet production with Etanorm SYT

Producing wood flooring is a hot topic. After the wood chips are dried out and glued, they are pressed into boards. This requires temperatures of up to 285 °C. To be able to use these extremely high temperatures continuously and evenly during production, heat transfer fluids are heated up and transported to the production facility. Where parquets are made, Etanorm SYT reliably supplies the presses used for MDF and particle board production with hot thermal oil.

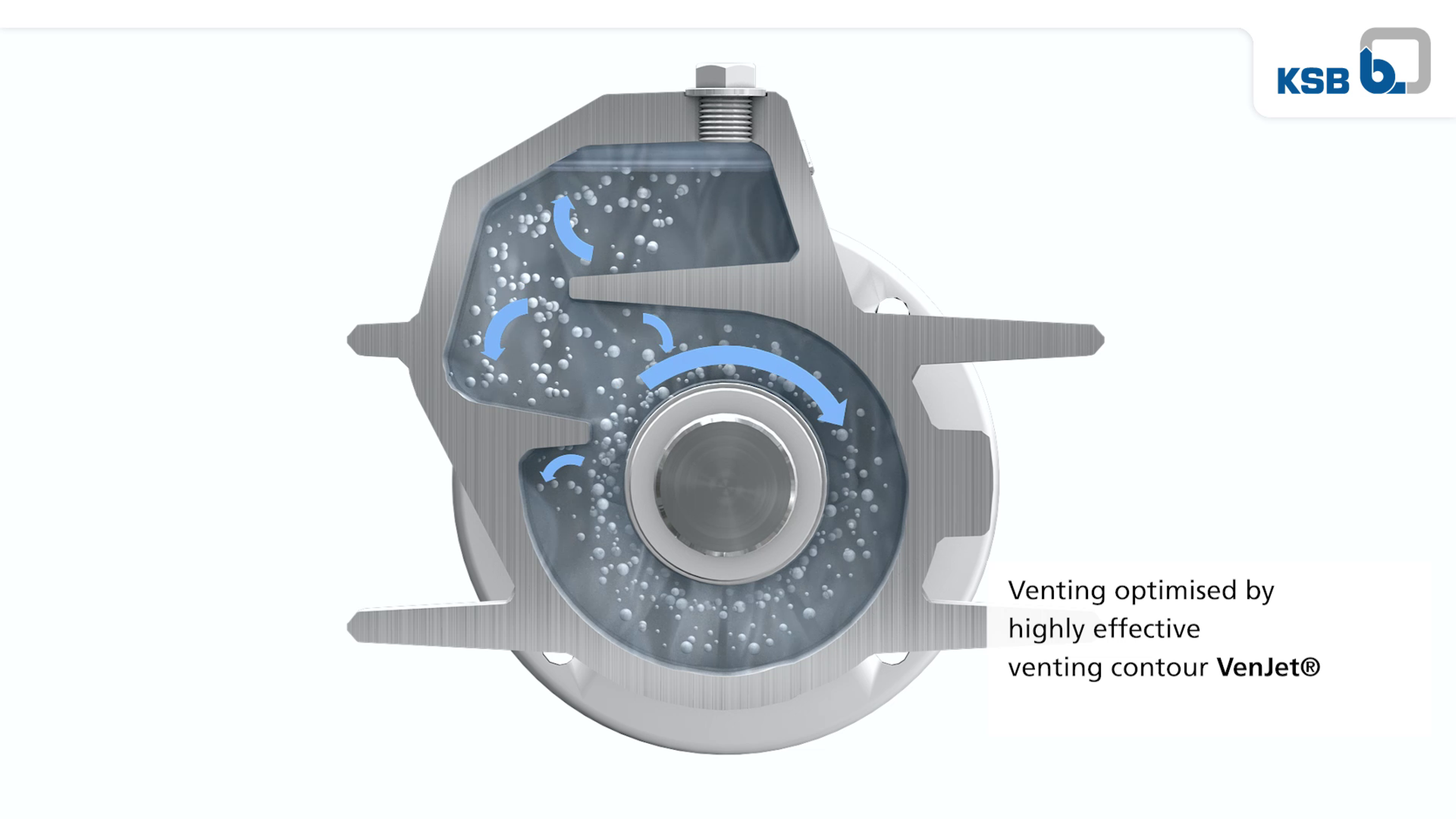

Intelligent solution for maximum operating reliability: the patented Venjet® venting contour

Operating reliability is of top priority in thermal oil applications. Safely venting the pump is part of it. KSB has developed a special patented solution that quickly and completely vents all gases contained in the fluid. The gases are collected in a separate chamber and are released in a controlled manner via a screw plug. On top of this, the mechanical seal chamber is completely filled with fluid, which prevents overheating and damage to the shaft seal.