- Maximum allowable axial movement

- 2 mm

- Minimum allowable axial movement

- -2 mm

- Component type series

- KSB Etanorm [B]

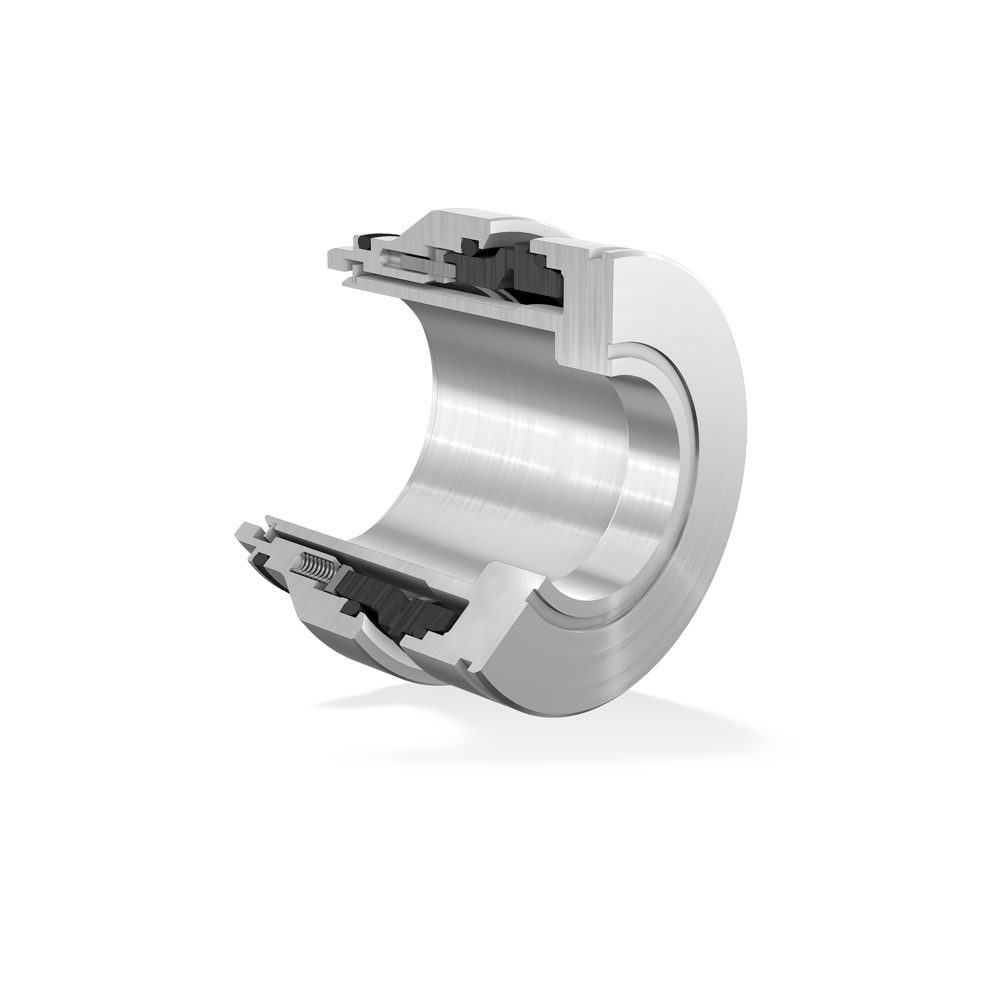

- Cartridge seal

- Yes

- Maximum allowable dynamic pressure

- 25 bar

- Design

- Stationary

- Balancing

- Balanced mechanical seal

- Sealing type

- Single

- Mtrl metallic compon.mech.seal

- 1.4571

- Mtrl mech.seal spring

- 1.4571

- Mtrl Secondary seal inboard

- FKM,

EPDM - Mtrl Mating ring inboard

- Q1 [SIC, DRUCKLOS GESINTERT],

U2 [TUNGSTEN CARBIDE, NI-BINDER],

Q7 [SIC,POROUS,SINTERED PRESSURELESS,NO GRAPHIT] - Mtrl Primary ring inboard

- A [CARBON, METAL-IMPREGNATED],

B [CARBON, RESIN-IMPREGNATED],

Q1 [SIC, DRUCKLOS GESINTERT],

U2 [TUNGSTEN CARBIDE, NI-BINDER],

Q7 [SIC,POROUS,SINTERED PRESSURELESS,NO GRAPHIT] - Direction of rotation

- Bi-directional

- Maximum allowable sliding velocity

- 20 m/s

- Spring design

- Multiple springs

- Maximum allowable static pressure

- 37.5 bar

- Maximum allowable fluid temperature

- 140 °C

- Minimum allowable fluid temperature

- -15 °C