Main Applications

- Chemical industry

- Petrochemical industry

Technical Data

- Cartridge seal

- Yes

- Design

- Dynamic

- Balancing

- Balanced mechanical seal

- Sealing type

- Double

- Maximum allowable fluid temperature

- 200 °C

Benefits

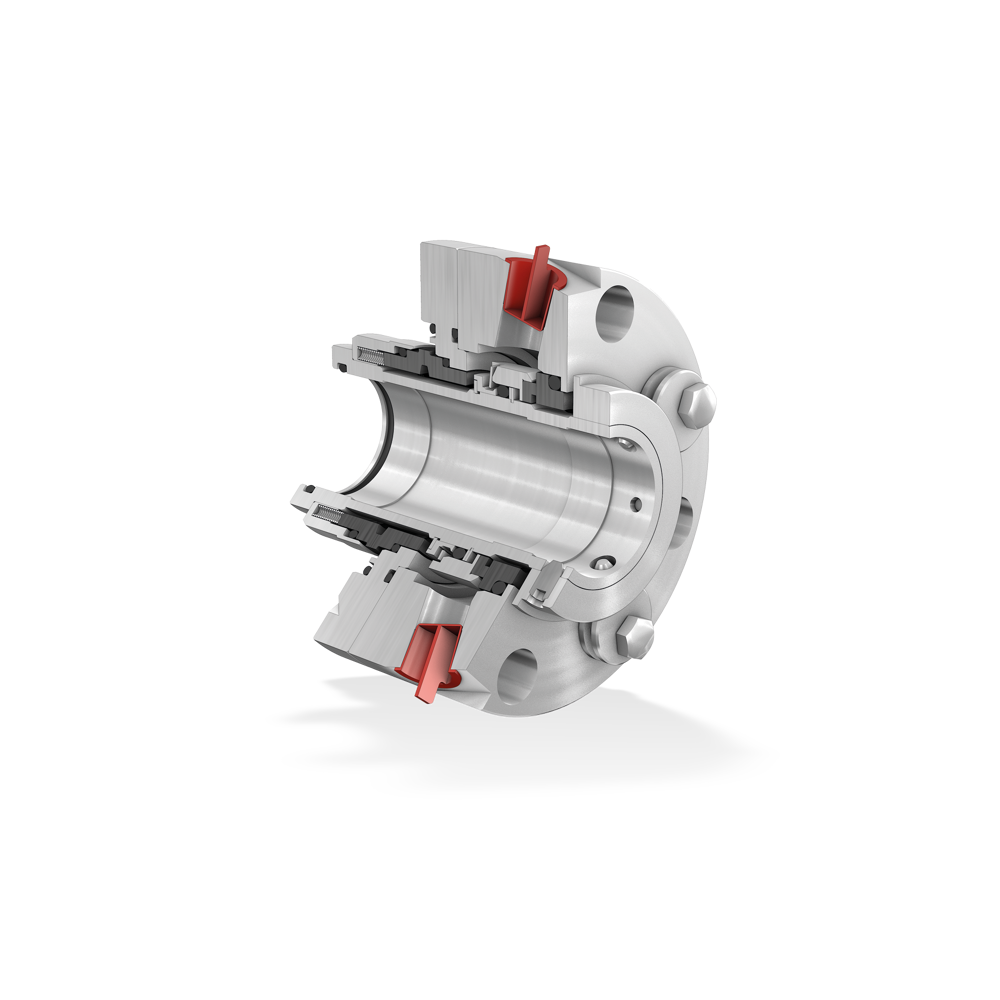

- The double cartridge seal is especially designed for use in the standardised seal installation spaces of the non-API pump MegaCPK (CPKN + CPK possible).

- The double cartridge seal can be connected in accordance with all common API Plans, such as 01, 02, 11, 31, 32 + 52, 53 (A, B).

- The space between the two mechanical seals is flushed with a buffer or barrier fluid, depending on the application. This completely absorbs any leakage of the fluid pumped. In addition, the heat is transported away from this area.

Technical Data

- Maximum allowable axial movement

- 1 mm

- Minimum allowable axial movement

- -1 mm

- Cartridge seal

- Yes

- Maximum allowable dynamic pressure

- 20 bar

- Design

- Dynamic

- Balancing

- Balanced mechanical seal

- Sealing type

- Double

- Mtrl metallic compon.mech.seal

- 1.4571

- Mtrl mech.seal spring

- 2.4610

- Mtrl Secondary seal outboard

- FKM

- Mtrl Secondary seal inboard

- FKM,

FFKM - Mtrl Mating ring outboard

- Q2 [SIC-C-SI, COMPOSITE]

- Mtrl Mating ring inboard

- Q2 [SIC-C-SI, COMPOSITE]

- Mtrl Primary ring outboard

- A [CARBON, METAL-IMPREGNATED]

- Mtrl Primary ring inboard

- A [CARBON, METAL-IMPREGNATED],

Q2 [SIC-C-SI, COMPOSITE] - Direction of rotation

- Bi-directional

- Maximum allowable sliding velocity

- 20 m/s

- Spring design

- Multiple springs

- Maximum allowable static pressure

- 20 bar

- Maximum allowable fluid temperature

- 200 °C

- Minimum allowable fluid temperature

- -10 °C