What are the benefits of the IEC 61406 and VDI 2770 standards?

On the way towards Industry 4.0 saving machine-related digital data plays a central role. In a "digital factory" this requires uniform standards and technologies for a straightforward exchange of data. We have put together a short video to explain the identification standards IEC 61406 and VDI 2770 and their many benefits. Watch the video now!

On the way towards Industry 4.0 saving machine-related digital data plays a central role. In a "digital factory" this requires uniform standards and technologies for a straightforward exchange of data. We have put together a short video to explain the identification standards IEC 61406 and VDI 2770 and their many benefits. Watch the video now!

A complete and uniform history file for each and every KSB pump and valve – for easy digital access

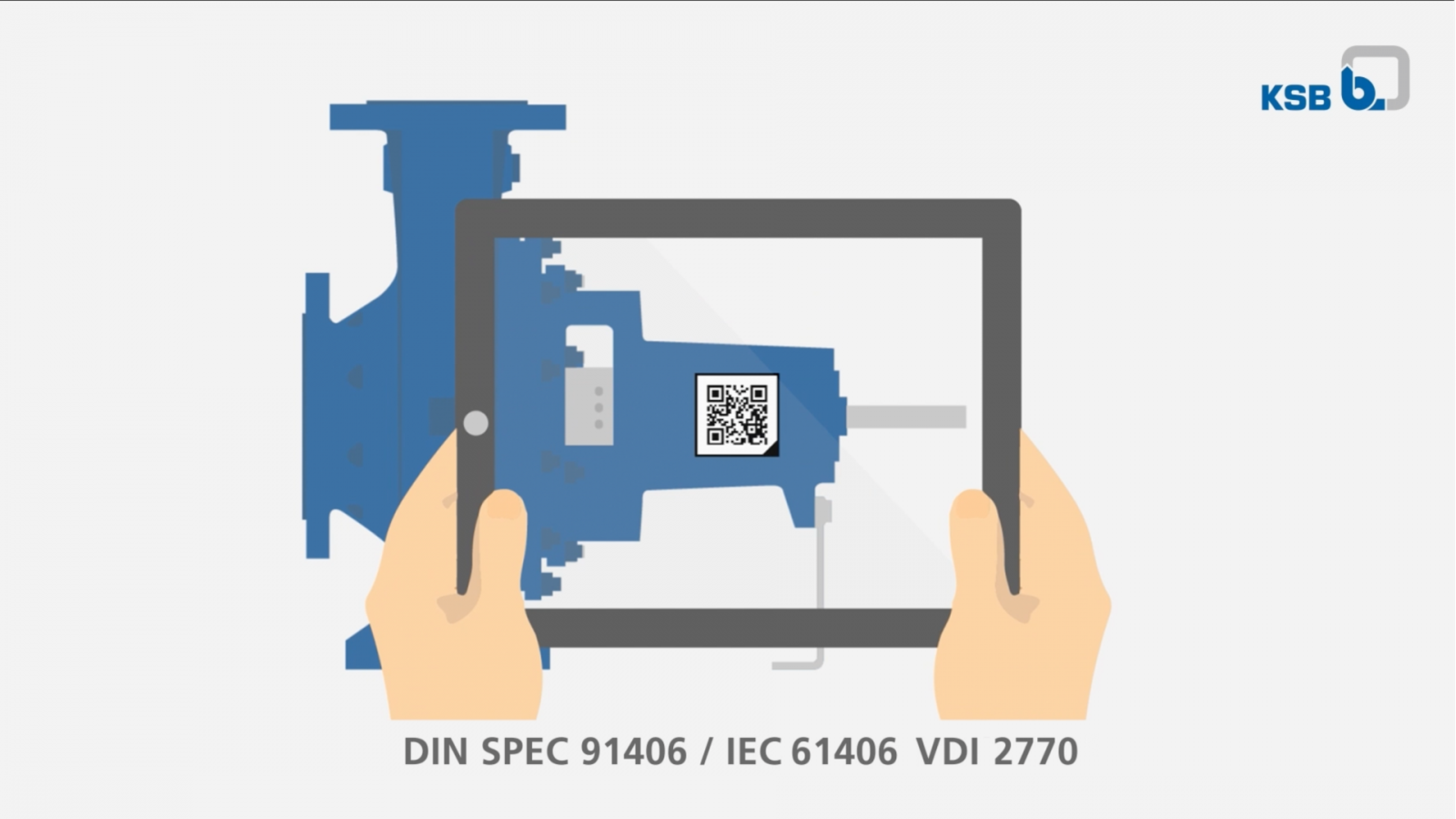

IEC 61406 describes the exact details of the digital name plate or, in other words, the unique identification of a product using its own, globally valid unique ID, also called unique identifier. This ID is a digitally readable name plate with QR code attached directly to the pump, valve or equipment and can be read out via a web-compatible mobile device. In this way, complete product documentations can be provided for the manufacturer and user.

The form in which this information is provided is regulated by VDI guideline 2770. It describes the classification, identification, format and structure of these digital data. The guideline defines the minimum requirements on manufacturer information that is relevant for the plant operators. The aim is to enhance the availability and exchange of information, thus optimising the operation of such systems and enabling the integration into other IoT solutions (e.g. KSB Guard).

In our film we provide you with a brief, well-structured overview of how KSB tackles these requirements and five concrete examples of the many different benefits resulting from the standards' implementation. Watch it now...

Compliance with IEC 61406 und VDI 2770 is requested more and more often by our customers. As KSB started looking into all aspects of digitalisation very early, we are among the pioneers in this field today. We are able to deliver our pumps and valves with all manufacturer information saved in accordance with the standards. Have you got any questions on this topic? Don’t hesitate to contact us.

Used Services

KSB Guard

The smart and comprehensive monitoring service for pumps and other rotating machinery, available 24/7 and also for non-KSB pumps. Benefit from predictive maintenance with KSB: comprehensive transparency, increased availability, enhanced operating reliability and efficient operation (of fixed-speed pumps). Important operating data such as vibrations, temperature, operating hours and load condition (of fixed-speed pumps) can be accessed via KSB Guard, anytime and from anywhere. In addition, deviations from normal operation trigger immediate notifications via the KSB Guard web portal and/or app. The experts at the KSB Monitoring Centre also provide support in analysing causes.